To improve the reliability of Yakutskaya SDPP-2 PRANA predictive-analytics system is being integrated at the plant

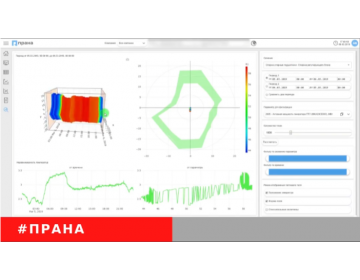

RusHydro PJSC and ROTEC JSC signed a contract to introduce the PRANA predictive-analytics and remote-monitoring system at Yakutskaya SDPP-2. PRANA is to monitor and predict the technical condition of 4 General Electric LM 6000 PF DF gas turbine units, 4 Brush turbo-generators, 4 КУВ-38.1-185 heat-recovery boilers, 2 Atlas Copco TP10T22D1 gas-booster compressors and 4 unit transformers.

Yakutskaya State District Power Plant-2 (SDPP) was chosen by RusHydro PJSC as one of the first facilities at which to introduce predictive analytics, since the power supply of the republic’s capital and 10 adjacent regions with a population of more than half a million Yakutians depends on the reliable operation of its units located in the permafrost zone.

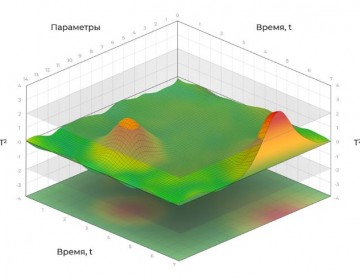

Implementation of the PRANA System at the Yakutskaya SDPP-2 will make it possible to promptly detect and prevent future faults, improve operational quality and fuel efficiency. The timely identification of emerging equipment defects will make it possible to assess the residual lifetime of elements of primary technological equipment and, as a result, reduce the frequency and cost of maintenance and repairs. Every second, the PRANA system registers and archives the entire volume of incoming online operating data from connected equipment, making it possible to improve the objectivity of repair-quality assessments, identify manufacturer defects, and ensure comprehensive service control.

RusHydro (http://www.rushydro.ru) is Russia’s largest power company in terms of installed capacity, combining more than 400 individual generating facilities. RusHydro is the country’s largest and world’s fourth-largest hydropower company, a Russian leader in terms of power generation from renewable energy sources. The installed capacity of RusHydro power plants, including Boguchanskaya HPP, is 39.8 GW.

ROTEC JSC (www.zaorotec.ru) is a company that specializes in the predictive analytics and monitoring of industrial equipment (PRANA system), design, engineering and general-contractor services in the construction of power-engineering facilities and infrastructure, the development and production of high-quality honeycomb seals for the aviation industry and power engineering, high-efficiency energy-storage and accumulation systems based on supercapacitors, as well as the manufacture, modernization and maintenance of primary power equipment.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices