Chemical Industry

- Accident prevention

HIF destruction can lead to incidents, accidents and casualties and significant material and environmental losses. - Control of inaccessible areas

Access for periodic inspection and control by instrumental methods is missing or hindered. - Prevention of operational disturbances of the unit

Shutdown for another HIF field survey can lead to a reduction in the lifetime of the equipment itself and to operational disturbances of the technological complex as a whole. - Reduction of periodic inspections.

If HIF has low damage tolerance. Its design features or technological functions make it inappropriate to conduct periodic inspection and control within a regulated time frame. - Condition-based operation.

Monitoring allows to increase the time between the routine outages for technical certification and, in the future, to switch to condition-based operation. - Financial costs reduction

Volume of preparatory works and works on the control over equipment requires its partial or complete shutdown, manufacture of special appliances for the inspection. It leads to significant costs and reduced operational efficiency.

Low-frequency vibration monitoring is the main diagnostic method for monitoring critical equipment in real time. A significant increase of low-frequency vibration is a result of the occurrence of a chain of defects, one of which necessarily has the greatest impact on the overall growth of vibration. Each of these defects has its own frequencies and its own characteristics, according to which it can be detected long before an emergency situation occurs.

As a rule, developing defects emit high-frequency signals that are not perceived by conventional accelerometers. Therefore, another method is used to detect developing defects at early stages - method of acoustic emission (AE).

PRANA system AE monitoring method provides additional opportunities in monitoring and predicting the state of chemical industry facilities.

One of the key advantages of using the AE method is that high-frequency signals quickly decay during propagation. This effect allows to monitor only the state of the assembly unit under diagnostics, in contrast to the low-frequency vibration, which extends to the entire unit. Technological, low-frequency interference does not have a significant effect on the signal waveform. In the high-frequency range, the main sources of signals are friction and micro-blows, which generate inharmonic oscillations.

Friction forces that excite high-frequency signals are stationary only in the absence of defects. Therefore, in defect-free assemblies both energy and amplitude of high-frequency signals are constant in time.

If microcracks occur, the nature of signals changes when the oil film breaks or when the lubricant gets contaminated. The bursts of high-frequency pulses appear, which are captured by acoustic emission sensors.

When monitoring with the use of low-frequency vibration data, only well-developed defects are detected, since a sufficiently large energy is required to excite the vibration. Less energy is required to excite high-frequency AE signals. Therefore, in responding to high-frequency bursts of energy, AE sensors can detect the incipient fault and prevent destruction.

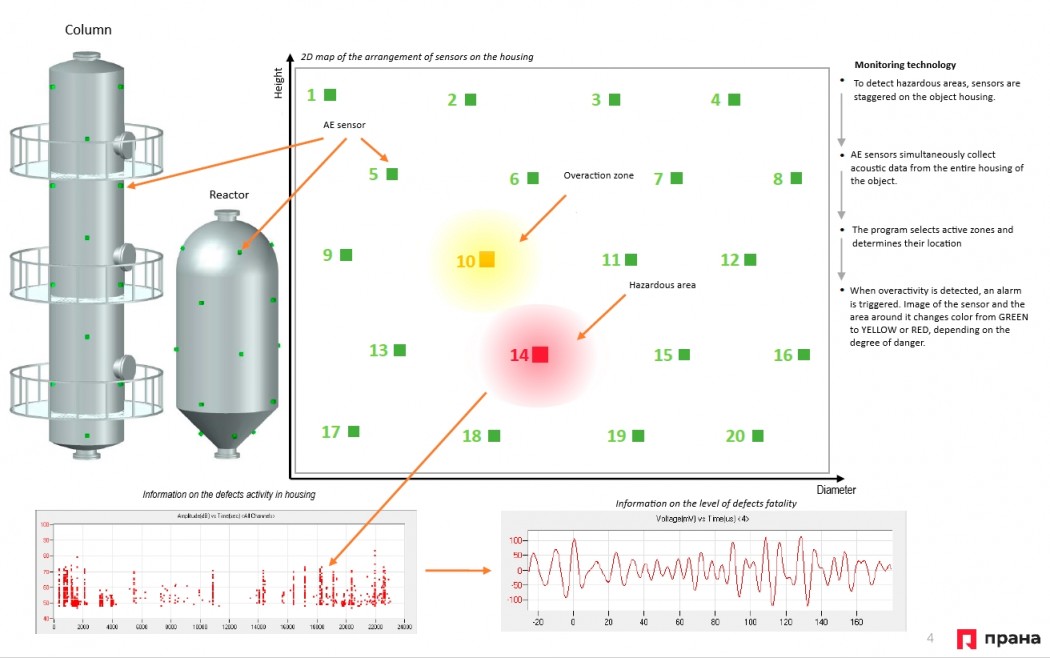

The size of defects is linearly related to the energy of the AE signal, which is emitted upon contact of friction surfaces. Knowing the maximum values of signals from the defects and defects growth rates, it is possible not only to determine the type of defect, but also to predict the time of trouble-free operation of the monitored element. To detect hazardous areas, sensors are staggered on the object housing. With their help, data are continuously collected from the entire housing of the object. The program selects active zones and determines their location. When overactivity is detected, an alarm is triggered.

AE monitoring process

- columns

- reactors

- containers

- vessels

- heat exchangers

- piping