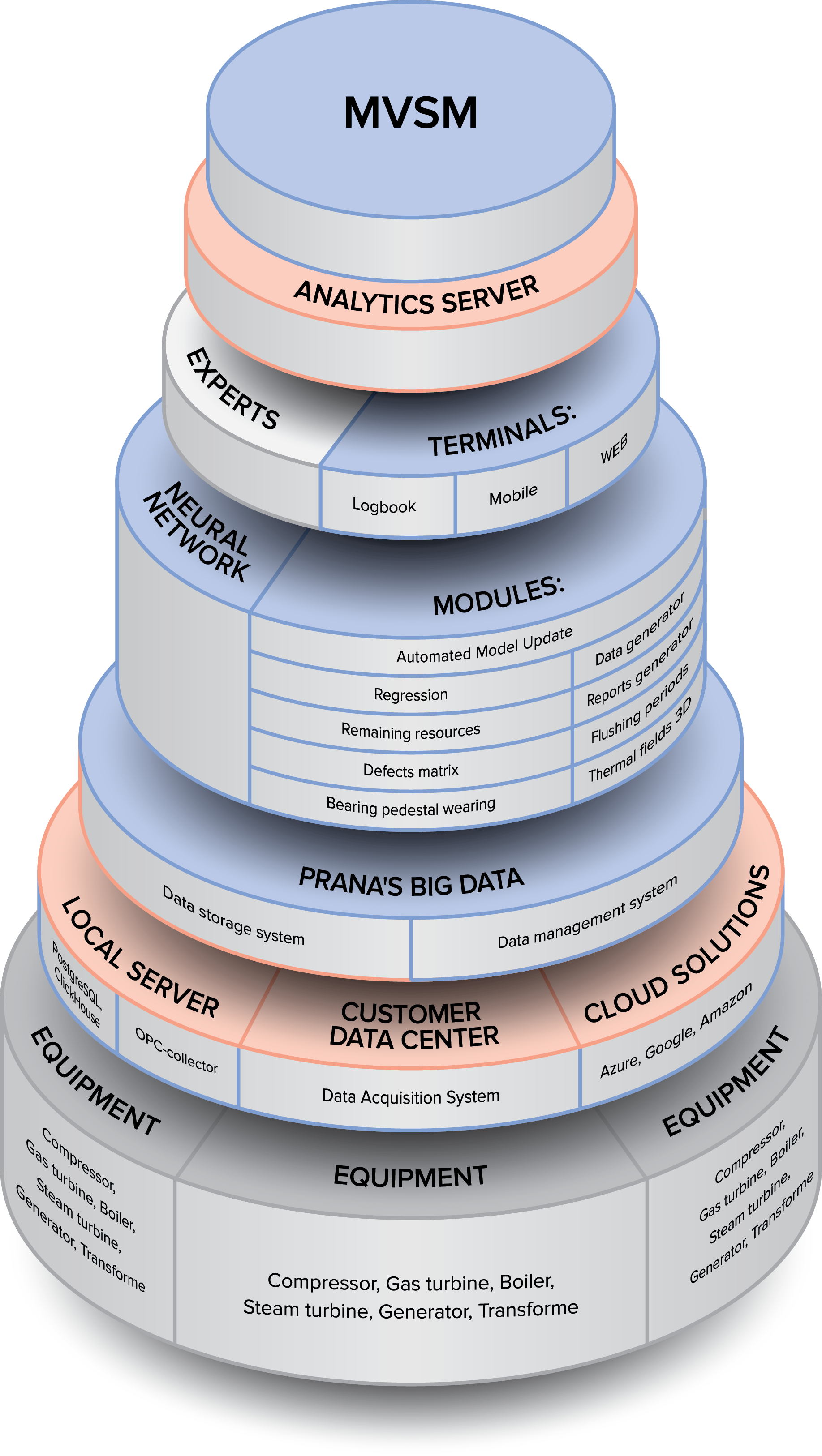

System Architecture

The MVSM-core (multivariate vector statistical model) is needed to create and play multidimensional models of the equipment state. They are digital images that describe how the equipment operates during the control period and in real time.

equipment operates during the control period and in real time. Playing models based on actual operational data makes it possible to identify deviating parameters in the operation of industrial equipment with extremely high sensitivity. This is the case even if they do not yet affect the state of the installation, which means they are not fixed by traditional control and monitoring systems.

The analytical server is located in the ROTEC Situational Center. The PRANA's server software powers the Situational Center. It includes a database storage and management system, an analytical device, as well as a server for client applications.

Experts with years of practical and academic experience in the field of power engineering work in the ROTEC Situational Center. Learn more about the PRANA team.

The PRANA system provides access to analytics data and source data archives through a client web interface and mobile apps. When organizing a corporate situational center, it is possible to install thin workstations maximally adapted for specific applications.

Over the years, the PRANA system has accumulated more than 5.5 TB of technological data in its archives. They include both sensor readings and automated analytics results. The flow of technological tags is marked by the relevance to malfunctions and deviations in equipment's operation. This allows us to train neural networks and other artificial intelligence algorithms. The first results confirm the effectiveness of this approach. The neural network we trained automatically detects the most common defects in gas turbine operation.

Additional application modules automate experts' work. For example, a module for 3D visualization of thermal fields shows the temperature distribution at the outlet of a gas turbine. By changing this pattern, an expert can judge the state of the compressor and the hot path of a gas turbine. Other ways of using the modules include the automatic calculation of the residual life of the equipment, taking into account start-ups and shutdowns, the calculation of compressor washing periods, and automatically updating digital models of equipment after repair or maintenance.

The PRANA forecasting system includes a feature to create intellectual archives about the equipment operation. Recorded technological data tags are automatically marked by identified deviations and supplemented by the results of experts' work. The resulting archive is used to train neural networks and other machine learning algorithms. The user can remotely access source data and the results of a detailed analysis at any time.

A local server is needed to collect and preprocess equipment's technological data. It is installed at the production facility, connected to the automated process control system and other possible interfaces. The local server establishes a secure VPN connection to the server of the Situational Center, and also includes a data diode router. It ensures the secure transmission of data and keeps the internal corporate network securely isolated from outside.