Feedback

Mosenergo PJSC confirms that with the help of PRANA, specialists of Rotec JSC carried out an analysis of trends in the operational parameters of the gas turbine units GTE-160 of one of the power plants of Mosenergo PJSC. The work was performed with sufficient quality, the results of the analysis were discussed at a technical meeting.

During the provision of the Remote Monitoring and PRANA forecasting service, changes in the technical condition of the connected equipment have been repeatedly identified. Experts and specialists of the center showed deep knowledge of technologies and equipment and promptly provided analysis of changes and recommendations for maintaining performance. The services provided by Rotec JSC help increase the reliability of equipment operation.

The introduction of the PRANA system at Kazan TPS-1 may become a new unique experience in introducing such systems of domestic development, which, according to the results of pilot production, can be replicated to the whole range of power equipment of enterprises in the industry.

A gas turbine outage is a major and by no means straightforward event. Plant personnel are to strictly adhere to the established procedure, and monitor numerous parameters. No wonder that slight performance deviations can be missed.

The human mind is unable to track the correlations between hundreds of diverse values. Instead, it can develop a prognostic system to help. Learn how PRANA finds concealed relations and reveals equipment defects.

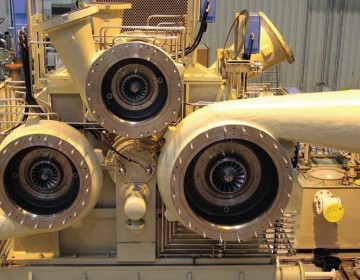

A cogeneration plant equipped with the PRANA prognostics system re-launched a BORSIG T-Jet 70-4 booster compressor after repairs. After the compressor had been started, a PRANA Situational Center operator noticed low primary gas pressure at the seals of compressor stages 1-4.