Точность прогноза

Обработано данных и используется для обучения нейросетей

Общая стоимость подключенного оборудования

Генерирующих мощностей подключено к системе

Время реакции системы на отклонение контролируемого параметра

ПРАНА – отраслевой стандарт будущего

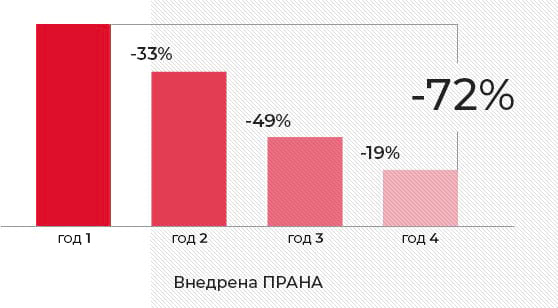

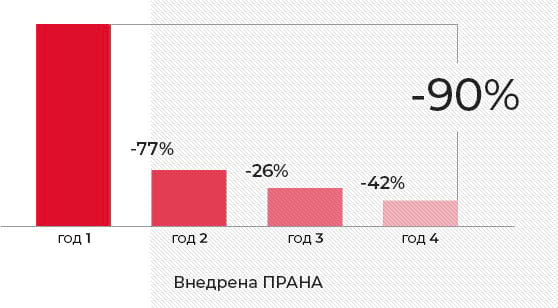

Экономический эффект от внедрения системы ПРАНА: снижение расходов на ремонт и рыночные штрафы до 60%

Индустриальное IoT-решение для диагностики и прогноза состояния промышленного оборудования с целью повышения эффективности его работы и снижения эксплуатационных затрат.

Для сбора параметров работы оборудования на промышленном объекте разворачивается нижний уровень Системы, позволяющий безопасно собирать и передавать данные в Ситуационный центр. Система ПРАНА в реальном времени анализирует данные, поступающие от работающего оборудования и автоматически выявляет любые отклонения, ранжируя их по степени вклада в формируемый дефект.

ПРАНА Экономическая эффективность

генерирующих компаний России:

Сокращайте внеплановые остановы

Система ПРАНА выявляет дефекты задолго до того, как они приведут к поломке. Все необходимые ремонты проводятся во время плановых остановов.

Снижайте расходы на ремонт

Раннее выявление дефектов позволяет не только избегать аварий, но и заранее планировать закупку запасных частей, оптимизировать логистику, снижать объем складских запасов.

Контролируйте персонал и оборудование

Оценивайте качество работы персонала и подрядчиков, контролируйте соблюдение условий и правил работы с оборудованием. Планируйте затраты и загрузку мощностей в реальном времени.

Выявляйте причины аварий

Анализ архивных данных позволяет выявить причины инцидента и проанализировать корректность действий персонала и поведения оборудования.

- Паровые турбины

- Газодожимные компрессорные станци

- Генераторы

- Трансформаторы

- Котлы

- Газопоршневые агрегаты

- Насосы

- Системы водоподготовки

- И прочее

- Газодожимные компрессорные станции

- Котлы

- Насосы

- Реакторы химические

- Электролизеры

- Мельницы

- Колонны

- Экструдеры большой мощности

- И прочее

- Газовые турбины

- Газодожимные компрессорные станции

- Котлы

- Газопоршневые агрегаты

- Насосы

- Реакторы химические

- Колонны

- Компрессоры для перекачки газов

- И прочее

- Трансформаторы

- Насосы

- Печи для обжига

- Доменные печи

- Сталеплавильные печи

- Электролизеры

- Мельницы

- Воздуходувки

- И прочее

- Котлы

- Газопоршневые агрегаты

- Насосы

- Дизельные двигатели и генераторы

- Редукторы и передаточные механизмы

- Электродвигатели

- Установки опреснения воды

- Газопоршневые агрегаты

- Насосы

- Главные вентиляторы шахт

- Мельницы

- Воздуходувки

- Дизельные двигатели и генераторы

- Редукторы и передаточные механизмы

- Электродвигатели

- Математический аппарат

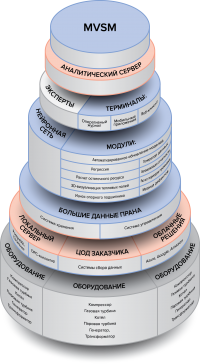

- Архитектура системы

- Ситуационный центр

- Наши услуги

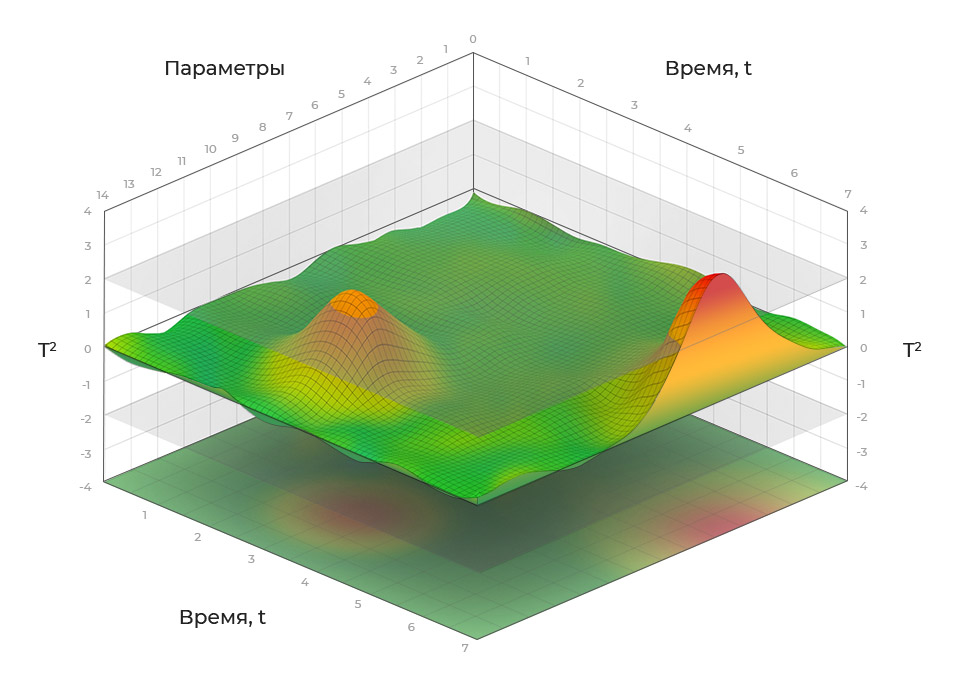

В основе ПРАНА лежит техника оценки многомерных состояний (MVSM).

Модель оборудования создается и настраивается на основе архивных данных. Отклонения в поведении выявляются с помощью единого интегрального критерия T2 и разладок параметров, ранжирование которых происходит автоматически, в зависимости от их вклада в отклонение. Данный подход разработан специально для мониторинга оборудования на атомных станциях, где надежность оборудования имеет максимальный приоритет.

Подробнее

MVSM-ядро (multivariative vector statistical model) необходимо для создания и проигрывания многомерных моделей состояния оборудования.

Проигрывание моделей по фактическим эксплуатационным данным даёт возможность выявлять отклоняющиеся параметры в работе промышленного оборудования с крайне высокой чувствительностью – даже если они еще не влияют на состояние установки, а значит, не фиксируются традиционными системами управления и мониторинга.

Подробнее

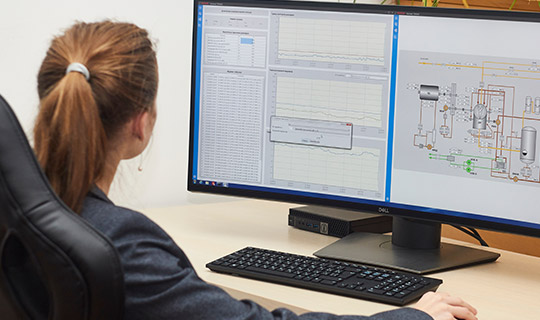

Ситуационный центр мониторинга предоставляет услуги круглосуточного наблюдения за объектом.

При малейшем отклонении диспетчер получает сигнал тревоги. Система автоматически определяет место и время возникновения инцидента.

Отклонения передаются в Экспертно-аналитический центр, где эксперты составляют заключение на основе автоматически сформированных рекомендаций по обслуживанию оборудования.

Подробнее

Ситуационный центр АО «РОТЕК» предоставляет услуги удаленного мониторинга и прогностики состояния промышленного оборудования.

В команду центра входят эксперты с многолетним опытом как научной, так и практической работы в области вибродиагностики и виброналадки, турбинного, компрессорного, котельного, тепломеханического и электротехнического оборудования.

Подробнее

ПРАНА используется для расследований инцидентов в российской энергетике. Одна из крупнейших страховых компаний России учитывает использование системы ПРАНА при расчете страховой ставки.

Один месяц необходим для установки системы на промышленном оборудовании большинства производителей без доработки или дополнительной настройки.

Математические алгоритмы ПРАНА универсальны и поддерживают любой тип оборудования - турбины, двигатели, компрессоры, насосы, котлы и т.д.

Самый большой архив данных среди независимых от OEM решений для предиктивной аналитики.

непрерывному контролю технического

состояния оборудования

системой ПРАНА

ежесекундно на каждом подключенном энергоблоке