About the basic product, the generation of axolotls and dummy investors

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production

The Ural Turbine Works, as a part of the ROTEC Group, has more than doubled its revenue after being renovated and retrofitted

In recent years, the power engineering ROTEC group of companies has stood out for noticeable growth within its industry. Over the past five years, ROTEC, as a company servicing power gas turbines, has managed to double its revenue and occupy 20% of the domestic turbine service market. After being renovated and retrofitted, the Ural Turbine Works, as a part of ROTEC Group, has more than doubled its revenue up to 9.3 billion rubles by 2020, mainly due to exports that currently are about 50% of the products manufactured. The UTW manufactures major generating equipment, including steam turbines and related high-capacity plants in Russia.

Presently, the scope of activities carried out by ROTEC Group covers not only traditional branches of power-plant engineering, but also the latest innovative trends in power industry. For example, the Group’s corporate network includes TEEMP, a manufacturer of supercapacitors. Moreover, ROTEC has its own successful development of a hardware-software package for predictive analytics for industrial equipment called PRANA and a number of other new projects. Perhaps, it is precisely this combination of traditional business, stable in its technological development and new technological projects that forms the particular attitude of the company’s management both towards innovations and towards venture capital financing, which is very popular throughout the world. We interviewed Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC and Honored Mechanical Engineer of Russia, in order to find out what the essence of this attitude is and how such different areas of the company’s activities are being developed.

Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Honored Mechanical Engineer of Russia

— What are the major innovative projects that have been implemented by your company over the past five years?

— What does the concept of “innovations” mean? Let’s look into the concept. We live in a world where the rate of change is constantly increasing. Therefore, the ability to adapt and live at a continuously accelerating pace is a factor of competitiveness. So, innovations mean the ability of a company to go on living in this rapidly changing world. If you do want to set the vector of market development and stay competitive instead of trailing behind the leaders, you must be able to make such “a wind correction”. In other words, your adaptation should be faster than the rate of change.

— Do you manage to keep pace?

— We aren’t trying to keep up with the changing world, we just live in it. And the main requirement set for the people who work for me is to be able to learn. Some people lose this ability when they are seventy years old, others — when they are eighty, and sometimes this ability is lost immediately upon graduation. To work for us, you have to develop your mind constantly, gain new knowledge, and be ready to adapt rapidly. Because we are doing a lot of things that no one in the country has ever done before. For example, we started to produce marine turbines for nuclear-powered ships that haven’t been manufactured for thirty years.

— In Russia?

— Not only in Russia. Both in the world and in our country, nuclear-powered ice-breakers have not been launched for thirty years. Accordingly, those people who used to be engaged in their design and manufacture did this in the old-fashioned way. Creating them in a modern way is not a trivial challenge. It is neither bad nor good: just think of giving a navigation ruler — that we used to apply in former times when studied at the flight school — to today’s navigator piloting an airplane, the navigator will not be able even to understand what the thing is intended for…

— And yet, what projects that can be considered innovative do you treat as the most significant in your company?

— First of all, it is the retrofitting of the Ural Turbine Works. When I got there, the average age of the staff members was sixty+ and the ceilings in the shops were leaking. At that point in time, the Works used to employ two thousand people, but they used to produce one turbine a year. Nowadays, the situation has changed a great deal: currently, one thousand two hundred people are capable of manufacturing fifteen turbines a year. And we are not limited to turbines. The enterprise equals any European or American turbine plant doing business in this model range. Besides, the Design Engineering Department is also in line with the state-of-the-art level. The time required for turbine design has almost been halved. The average age of our DED staff members is thirty+. And throughout the Works, it is about forty-six. The mode of production has also changed due to up-to-date methods of design, modeling, creation of state-of-the-art equipment.

— But the Works modernization more likely refers to the operating rather than innovation activity..

— Not at all! It is the innovation activity in all its glory. Because the entire structure has changed.

The time required for turbine design has almost been halved. The average age of our DED staff members is thirty+. And throughout the Works, it is about forty-six. The mode of production has also changed due to up-to-date methods of design, modeling, creation of state-of-the-art equipment.

— What is the share of R&D costs in your revenue?

— It varies in different businesses. It depends on the degree of development of the business line itself. In the case of storage units (supercapacitors are manufactured by TEEMP included in the ROTEC Group. — Stimul), R&D costs there are twenty percent so far. In the case of turbine production, it is about five percent.

— What projects implemented at the Ural Turbine Works are these funds primarily spent on today?

— The UTW is traditionally within the market zone of Russian power industry. And our power industry has its unique features. It is extremely inclined towards the stop-and-go manner. Previously, there was the DPM-1 program (power supply contracts secure a mechanism for a guaranteed return on investment for new power generation facilities, — Stimul) and everyone was building new power units, purchasing American and German gas turbines.

Currently, the DPM-2 program is underway and the country is retrofitting old power units. In this context, it is obvious that DPM-2 is a consequence of DPM-1 because at first, everyone was building new generation facilities and there was literally no money left to maintain and retrofit old power plants.

We couldn’t follow this logic, so we decided that traditional power industry at our Works should not amount to more than fifty percent of the order portfolio. The remaining fifty percent of our load (sometimes more) is export orders or turbines for other types of generation.

The first turbine for waste incineration plants of a new series – Kp-77-6.8

For example, we started manufacturing new turbines for waste incineration plants. These are new technologies despite the fact that the basic engineering is done by Hitachi Zosen, a Swiss company. We designed a turbine in compliance with their requirements. It was made from scratch, there was no such thing in the country before. This turbine has an axial exhaust in the same casing. We are counting on its export potential.

Another new type of product and our development is ship turbines. We haven’t manufactured them before either. We have designed from scratch a power unit for a large linear nuclear-powered ice-breaker of the Leader series that is now being introduced at the Zvezda Shipbuilding Complex.

The same goes for exports. Even though turbines cannot change the physics, the operating conditions are of importance as well. The turbines to be operated in Ulaanbaatar are manufactured in a slightly different way than those that generate energy in Moscow.

All of this is necessary in order to balance the Works’ portfolio and mitigate the risks caused by potential market fluctuations. We have a lot of work to do on this.

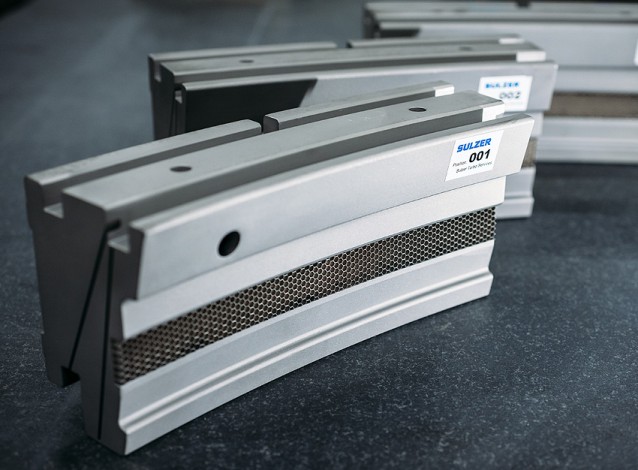

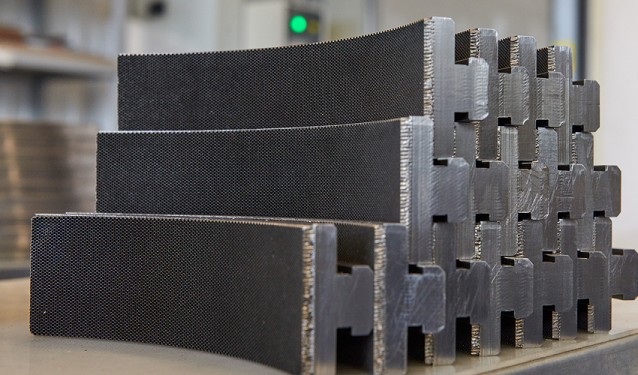

Moreover, the struggle for fuel efficiency, for high performance coefficient, resulted in the need to develop honeycomb seals. This is a true technological innovation that we have introduced in the country from scratch.

— Could you, please, explain what honeycomb seals are?

— A turbine has a rotor, a stator, blades, and a gap through which the working fluid “idly” flows over from the high-pressure zone into the low-pressure zone that results in the loss of efficiency. It is impossible to absolutely minimize this gap because of thermal expansions. Accordingly, we have to lay something between the stator and the rotor in order to fill this gap, on the one hand, but retain the capability of rotating, on the other hand. And since we are struggling for every proportion of the efficiency percentage, such seals — especially in the hot zone of the turbine — become a critical element in the machine competitive ability. This is especially noticeable in jet aircraft engines. The technology of manufacturing modern honeycomb seals for turbines was available in America, England and China. Now, there is one in Russia. (See a honeycomb seal element in the photo below.)Honeycomb seals for General Electric 6FA gas power turbine

We developed the technology for manufacturing the seals from scratch. It is impossible to buy the equipment for their manufacturing since it is simply not offered for sale. There are only seven companies in the world that make such a product and none of them will even let us approach the door behind which it is being produced.

— Do you mean that you have also developed the equipment for manufacturing the honeycomb seals?

— Exactly! This is entirely our development.

— Well, this is a true innovation, I am at a loss for words…

— Quite so! We are the only one who managed to do this throughout continental Europe after the UK left the European Union.

— Is this technology based on some previous developments inherited from the Soviet period?

— No, it isn’t. This is a state-of-the-art technology. Many modern technologies were not available during the Soviet era, but luckily we can apply them today. In light of the possibilities offered by our components, the very designs of aircraft engines started to be modified in order to fit them. All this happened in the course of a year and a half, maybe even less. Over a year, we obtained a license for the design and manufacture of aviation products from the Ministry of Industry and Trade of Russia. Today, our honeycomb seals are used in all and every new jet engine produced by our homeland. Additionally, we manufacture seals for General Electric, Rolls-Royce turbines, and design them for Siemens turbines.

— How do you conduct technological forecasting in your company? Do you have any research center?

— Our entire business is a research center. Once again: the ability to learn, the ability to accept information from the outside and comprehend it appropriately are the principal skills to be nourished by us.

We started manufacturing new turbines for waste incineration plants. The basic engineering is done by Hitachi Zosen, a Swiss company. We designed a turbine in compliance with their requirements. It was made from scratch, there was no such thing in the country before. This turbine has an axial exhaust in the same casing.

— Where is the decision-making center located then?

— Our decision-making center is utterly traditional and represented by the Board of Directors. We have the management, the Board of Directors, the Design Engineering Department — not only one, but three Design Engineering Departments dedicated to different areas of activity — and people who are capable of living in the information landscape. They monitor what is happening in the world. It is necessary to fully understand the technological and market landscapes. Any industry innovations must be familiar and in the public eye and this is the responsibility of every person in our company. This also determines the company’s viability.

But if you want to ask me if we have some kind of S&TI Department, the answer is no.

My office door is always open. If someone has a fresh idea, they can always come and tell met: “Look at what I dreamed up!” Thereafter, we will think about what to do with this. Or otherwise: “Just look, the Americans produced a new photoconverter cell. Now, they have an efficiency of sixteen percent, but it is expected to reach eighteen at the end of the year. If they continue at this pace, they may outperform us within five years.” If the DED engineers do not see this, they will never design anything really efficient.

TURBINES AND RES

— Turbine construction technologies are not undergoing any fundamental changes, but for a long time in the Russian turbomachinery industry, for some reason, there has been a hitch associated with a gas turbine of greater capacity, an electric capacity of 110 MW and higher...

— There was no hitch at all. Do you know where the state-of-the-art and coolest Alstom gas turbine was designed? In Moscow, at the enterprise called Uniturbo. It was a subsidiary of Alstom that used to design the turbine hot section. This is by the way.

The problem is different. The problem lies in the staff. One of the colossal mistakes that has been made in recent years is how the educational system has been treated in our country. Everything that had been accumulated was simply buried. Therefore, now, we just have a generation of axolotls, i.e., amphibians that reach the state of puberty and never turn into an adult. The same refers to the staff that originated from our educational system. They only wear jeans and sneakers. And this is because of our horrendous experiment in education.

Today, our honeycomb seals are used in all and every new jet engine produced by our homeland. Additionally, we manufacture seals for General Electric, Rolls-Royce turbines, and design them for Siemens turbines.

— Do you mean that you feel this?

— Surely. The problems in engineering come from here. And now I’ll answer your question about the gas turbine. When some staff members in our company brought up the subject concerning the gas turbine manufacture, I asked them the following simple question: “Can you show me the demand for ten pieces a year for ten years ahead? If you can, we’ll produce it, but if you can’t, I am not interested in it.” Nobody was able to show me.

Nowadays, in the context of the global trend, power industry is moving towards the diminution of single generation instead of its enlargement. What is currently being produced by even the nuclear industry, our most trend-setting sector? This is Ritm-200 (a pressurized water nuclear reactor with an electric capacity of 55 MW. Designed to be installed on ice-breakers and floating nuclear power plants. — Stimul). Turbines with a capacity of a thousand megawatts are no longer needed there since a hundred megawatts are enough. There are some reasons for that. People revise their attitude towards everything — food, water, energy — all this changes the face of the planet. And the ongoing disintegration of power industry, partly owing to digital technologies, raises a big question: does the world still need large gas turbines at all?

It is obvious that large capacities are inevitable in such agglomerations as, for example, Moscow, in cities with a population of one million or more. But if the population density is low, it is necessary to use other machines.

Today, we can see the pronounced crisis of overproduction: the number of turbines that may be produced by Siemens, General Electric and Mitsubishi is much larger than the number of turbines that may be purchased by customers now. So, the subject of a large turbine is switching from economics to politics, at the level of cross-country competition.

— The crisis in overproduction in the gas turbomachinery industry occurred, probably, partly owing to the extremely intense development of renewable energy sources that are displacing traditional power industry, didn’t it?

— The expansion of RES is somewhat a hype, politically, and artificially motivated. On the web, there is a photo of a graveyard for wind turbine blades located in America. It depicts an enormously vast area with the topsoil removed, these blades have been spread over the ground and covered up. Used wind turbine blades can’t be recycled and therefore they are being quietly buried.

Graveyard for wind turbine blades in America

In the context of solar power, people began to think about imprinting agricultural lands. By the way, in my previous interviews given seven years ago or so, I asked: where are these solar fields being placed? Where people live. Moreover, they grow tomatoes over there. Thus, if you “imprint” with solar modules the place where you can produce food, then you can die of hunger, but with a light bulb turned on. In this case, one should have common sense.

— Do you manufacture turbines for windmills?

— No, we don’t. We aren’t engaged in manufacturing turbines for windmills. We considered this area of activity, but when state-owned companies enter the subsidized zone, from my point of view, then there is no place for private business there.

— Nevertheless, your portfolio still includes solar power. Do you see any prospects for it in Russia?

— Of course! There is common sense in this after all: we have zones with sufficiently high insolation, there are many of them, and we have zones with low population density as well. In the context of a village that has been supplied with power from a diesel power plant for many years, then the availability of solar generation there can reduce diesel consumption by thirty to forty percent. In such circumstances, the economic component is quite obvious. The idea of installing solar generators on roofs is also viable: plants, warehouses, cooling towers, and power plant buildings... And only then ground-based solar farms. We equipped hunting and research stations with independent energy sources in the nature reserve located in the Russian Far East, where Amur tigers live. It is efficient and very convenient. Therefore, you cannot simply state that this is good while that is bad. It is necessary to avoid situations as the proverb says “give a fool enough rope, and...”.

Welded honeycomb seals for power turbines

VENTURE LOGIC: FUNDRAISING RATHER THAN CREATIVITY

— What’s your attitude towards venture capital investments?

— It’s a horrendous story! It originated not in the venture capital market, but much earlier, in the eighties of the last century, when family-run businesses began to transform en masse into public companies. It was then that the transition from basic to stock-derivative business value started. In the late nineties, corporations began to move R&D departments outside the business perimeter.

And since 2010 or so, an enormous number of managers have shown up who live and think adhering to the following logic: you can decorate something in the right way, make a presentation and, as they say, raise funds rather than the logic you can “create the best product or service and sell it.” There is even a specific term — fundraising. An entire generation has grown up not adhering to creative logic, but the approach “What have you done? I’ve raised funds!”

This is true for the entire generation. This huge fundraising industry in general distorts human consciousness very strongly. We do not create anything at all, but we are successful traders in financial derivatives on the stock exchange.

— Nevertheless, the venture capital market gives rise to such people like Elon Musk. Isn’t that right?

— This wasn’t the starting point for Elon Musk.

— However, he is getting resources from the very venture capital market machinations you are blaming…

— If Mr. Musk had to live in our innovation support system, he would already have been imprisoned for his first project, for misuse of funds. Abroad, the situation is as follows: if things went wrong, go ahead and try again.

Even though the stir about Mr. Musk is pretty cooked up, he is an undoubtedly gifted and definitely brave person, and he really has opportunities that we cannot get here.

Neither the Internet nor the microwave oven originated from fundraising. These tools are important and I don’t have any illusions in this respect. However, a huge number of innovations that came from the United States still come from the state support system — either by means of contracts or financial assistance, for example, via DARPA.

One of the colossal mistakes that have been made in recent years is how the educational system has been treated in our country. Everything that had been accumulated was simply buried. Therefore, now we just have a generation of axolotls, i.e., amphibians that reach the state of puberty and never turn into an adult.

Abroad, people acquire the right to make a mistake along with the support, but in Russia the situation is the opposite. And you cannot accomplish anything without this. I mean, if you propose something new, it may either work out or not. Always. And if money is given, then it is given to a particular person and not to a project. Money was given to Mr. Musk. And when he made mistakes, he was given more money. Why? Because they believed that he would succeed in the end. It was the case even in our Soviet system, you have only to remember the number of failed aerial vehicles. You should visit the Aviation Museum in Monino that exhibits a lot more failed attempts than successes.

In the today’s system of coordinates, if you failed, you could be sent to the Accounts Chamber and the Prosecutor’s Office. The end.

Nevertheless, despite the existence of Elon Musk and a number of other talented entrepreneurs, the venture capital market, in terms of staffing, brings up people whose life attitude is not to create a winning product, but just to raise funds. And that’s discouraging.

If we look at history, where did all this come from? Major corporations used to be established by families or business leaders and the first blow to this conservative industrial community was delivered during the period of depriving companies of their public nature. As soon as the generation of public company managers grew up, they began to think not in terms of products, but in terms of the value of shares, which often has nothing to do with the fundamental business value. As a result, the planning horizon ceased to be a long-term horizon, but turned into a short-term horizon of the quote period, quarterly and annual reports. It is evident that R&D departments having such priorities became burdensome and their massive reduction started.Where are these solar fields placed? Where people live. Moreover, they grow tomatoes over there. Thus, if you “imprint” with solar modules the place where you can produce food, then you can die of hunger, but with a light bulb turned on.

— Nevertheless, these startup machinations sometimes succeed quite successfully. Isn’t that right?

— That’s what I tell you: Ilyushin DED also used to come through and buzz every bit as well. And by the way, Lockheed also succeeded without any startups and even now it sometimes comes through. I mean, “sometimes comes through” is definitely a positive thesis and it is an exception as in the case with Mr. Musk. We can see Mr. Musk, but we do not see the thousands of startups left behind that raised funds due to investors, deceived everyone, closed down, and decided to start up something else. It is an entire colossal industry of fleecing dummy investors. Undoubtedly, there are talented guys, undoubtedly, they achieve a certain success. But, unfortunately, the story itself is currently very erroneous.

— However, it is justified by the fact that it is true that only one in a thousand really succeeds, but it excuses all the costs and expenses incurred by the market…

— Firstly, no one ever counted up these costs, secondly, this worked when Steve Jobs was designing something in his garage in California. But nowadays, the situation is different. Today, people churn out a presentation and try to shove it down the investors’ throats. Mr. Jobs managed to make a computer in his garage. By the way, I am happy to communicate with people who come and tell me that they have designed something in their garages.

— What methods do you personally use to find ideas, teams, and support them? Do you invest in such external teams in the hope that they will be of some benefit to you? Do you use the so-called “open innovations”?

— If inventors come to us, I carefully examine their inventions and study the way they managed to achieve this. I consider how we can somehow integrate them and discuss the terms and conditions for our cooperation.

— Do you necessarily integrate them or can they work from the outside?

— They can work on a contract basis from the outside. This is how we cooperate, for example, with Cyberphysics Company from Skolkovo. This is a standard contractual scheme: they do some work and I pay them for it. From my point of view, it is the most appropriate way.

— At what stage do you understand that you may invest in them? Have you had such examples?

— I have invested money in Datadvance Company. Because it seemed to me that the people who work there are the right people who may be given money. I myself am interested in what they do.

— What does Datadvance do? Why did you choose them?

— They make complex software. System modeling that is used by almost all designers at Dassault and Airbus. This is modeling of products and processes.

Turbine assembly in the shops of the Ural Turbine Works

E-MOBILITY. JUST COMMON SENSE

— So, you deal with supercapacitors and batteries that are used in electric vehicles. What is your opinion about electric mobility prospects?

— I will repeat myself and say that I support the multistructurality and common sense. For example, in Moscow an electric car is the most polluting travel method. Just as the case in Europe, by the way. Today, the main beneficiaries from the introduction of electric vehicles are, firstly, oil companies, and, secondly, environmental egoists. Both of them are vicious since they think as follows: let it be clean here at my place while it will be dirty on the outskirts where СНРP is located! Because, instead of burning fuel on board, they burn it at stations with an efficiency that is worse and even associated with delivery losses. As a result, instead of burning a liter of fuel in the car, they will burn several times more at the power plant.

But if we talk about electric ground movement, then its key element is the ability of the electric motor to turn into a generator when braking. By accumulating the kinetic energy of braking and releasing it when accelerating, we gain real efficiency. I mean, the outlook lies in electric mobility with the possibility of recuperation. Another question is where the primary energy source is located. Currently, its availability on board is the most environmentally and user-friendly option. Because the degree of wear and tear on electrical networks in Europe, America and Russia is identical. All of them were built in the 1970s and haven’t been retrofitted since then, therefore there are substantial losses everywhere.

A new generation has grown up not adhering to creative logic, but the approach “What have you done? I’ve raised funds!” This is true for the entire generation. This huge fundraising industry in general distorts human consciousness very strongly. We do not create anything at all, but we are successful traders in financial derivatives on the stock exchange.

— Does your R&D portfolio include a project for such a vehicle? I mean a vehicle equipped with such a hybrid recuperative engine.

— No, it doesn’t. We are not trying to create such a vehicle because there are many people who are already doing this. But we do produce supercapacitors designed to recuperate that very energy.

— Is it in demand today?

— Unfortunately, or perhaps fortunately, the project emerged prior to the market. In fact, we are establishing this market right now.

— How do you manage to sell your supercapacitors then? Who are your customers?

— There are many applications, the very same recuperation, for example, is very useful in street cars. We are currently conducting an experiment in St. Petersburg. You know that if two street cars start off concurrently, they “drop” the substation. Because the substation does not retain the current that they take on. The same happens when they are braking concurrently. Due to the parasitic current that is generated in the electric motor and released into the network.

We can see Mr. Musk, but we do not see the thousands of startups left behind that raised funds from investors, deceived everyone, closed down, and decided to start up something else. This is an entire colossal industry of fleecing dummy investors.

Tests have shown that when street cars equipped with supercapacitor-based systems start off concurrently within the same section of the contact-wire system, it is not affected at all. Because the entire volume of start-up current is stored in the capacitor unit and it is accumulated during the same street car braking prior to stopping. Moreover, this energy is enough to reach the next section in the event of a loss of voltage in the network.

Supercapacitors also perform well at cold temperatures, unlike batteries. One and a half thousand diesel locomotives are already using our start-up systems in order to be able to turn off in winter. What was it like before? A shunting diesel locomotive started up in the morning and didn’t turn off all day long, because if it turned off, it wouldn’t start up again. The capacitor start-up enables it to turn off and on at any time. Seasonal fuel savings, together with the decrease in environmental load, are about thirty percent. Here we should pay tribute to Russian Railways. The company is thoroughly involved in such innovations and is creating a systemic smooth demand.

Source: STIMUL

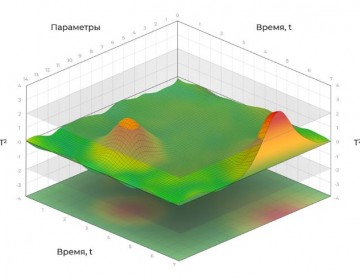

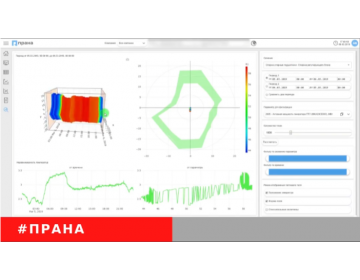

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices