Russia’s PRANA Predictive Analytics System is coming to Kazakhstan

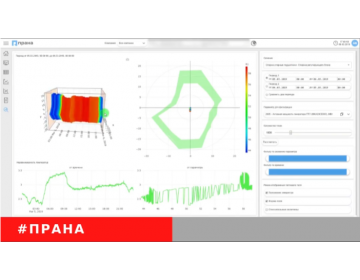

АPAVLODARENERGO JSC became the first foreign customer of the PRANA predictive analytics system and a leader in predictive analytics systems implementation in the country. The state-of-the-art technology will ensure the reliability and safety of the power generating equipment of generator-transformer unit No. 6 at CHPP-3 in the city of Pavlodar (Kazakhstan). The T-120/130-130 PR2 steam turbine manufactured by the Ural Turbine Works, and the generator and 6T TDTs-160000/110 generator transformer of Power Machines – Toshiba. High-Voltage Transformers are connected to the system. The total capacity of turbine unit No. 6 is 125 MW.

“The use of state-of-the-art solutions and developments is the basis of our technical policy. We plan to use digitalization and the implementation of smart systems to improve the economic efficiency and reliability of the equipment. After a thorough investigation of the market, we decided on the PRANA prognostics system, which had already proved to be efficient in Russian companies in the power industry,” noted Oleg Perfilov, General Director of PAVLODARENERGO JSC.

“By upgrading the fleet of steam turbines at CHPP-3 of PAVLODARENERGO JSC, Kazakhstan’s energy suppliers have de-facto confirmed their interest in the trouble-free, predictable and effective functioning of modern power generating facilities. In the conditions of competitive market, it is very important to provide reliable protection for expensive equipment, and to ensure the safety of personnel and the company in general against potential accidents and unscheduled equipment shutdowns. Our system of predictive diagnostics, which has proved its efficiency, is capable of preventing abnormal situations and saving considerable amounts of money for the customer. By equipping their energy facilities with the PRANA system, the professionals of PAVLODARENERGO JSC have established a new high standard of safety and responsibility for the entire region,” Artyom Markelov, Head of PRANA System, commented

In addition to basic energy equipment, PRANA will be used to monitor the condition of the turbine unit’s foundation. ROTEC specialists equipped the facility with an integrity monitoring system based on an acoustic emission method, as well as a set of sensors for determining temperature, deformation, tilt angle, vibration and linear displacement. Using this data, PRANA will be able at the earliest stage to detect the formation of cracks and material degradation due to vibration from the turbine unit, and to assess column deviations, as well as the smallest movements in the foundation. Data on the facility’s condition will be taken into account when analyzing the operation of the main equipment of a turbine unit, which will further increase the accuracy of forecasts and the efficiency of the solution.

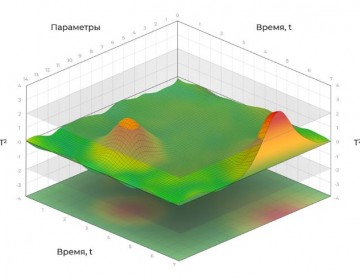

The PRANA Predictive-Analytics and Remote-Monitoring System (https://prana-system.com/) is an industrial IoT solution that identifies defects in the operation of industrial equipment 2–3 months prior to possible accidents. The system combines methods of statistical analysis, digital product imaging, an instrumental technique for working with big data and machine-learning technologies.

PAVLODARENERGO JSC (http://pavlodarenergo.kz/ru/) is a vertically integrated company, including all elements of energy supply in the Pavlodar Region (generation, transmission and sale of energy resources). The company supplies electricity to the territory of the Pavlodar Region with a total area of 105,900 square kilometers and a population of 754,000 people.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices