ROTEC shares its experience with digitalizing facilities in the power industry at the Second International Energy Saving Forum in Astana

The Second International Energy Saving Forum was held on November 29 in the capital of Kazakhstan, timed to coincide with World Energy Efficiency Day. The Forum in Astana united professionals from 10 countries and served as an annual platform for dialog to discuss the issues of the digitalization of industry, the role of energy saving and environmental protection, and the improvement of information awareness on new opportunities.

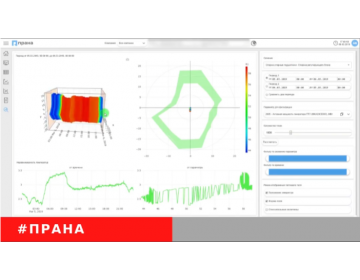

ROTEC’s experience in the digitalization of energetics and the capabilities of the PRANA prognostics system were presented by Artyom Markelov, Head of digitalization activities. Within the framework of the “Digitalization of Industry – the Hidden Potential of Energy Efficiency” session Mr. Markelov made specific mention of the experience of Kazakhstan’s energy engineers, who were among the first in the CIS to begin the integration of automated equipment packages and intellectual systems at power generating facilities.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

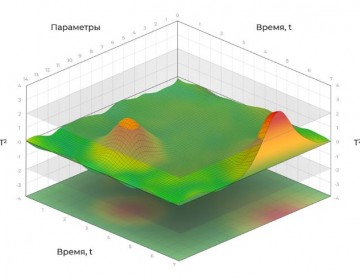

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices