PRANA Predictive Analytics System will be able to calculate Technical and Economic Indicators for Industrial Facilities

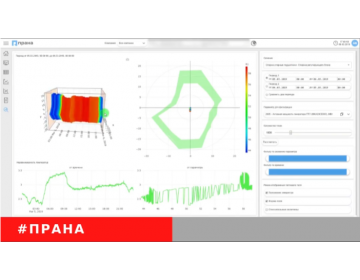

Experts from the PRANA Predictive Analytics and Remote Monitoring System have started an alpha testing of a new software and data system capable of tracking and providing calculation of technical and economic indicators (TEI) for the connected facility in 24-hour automatic mode.

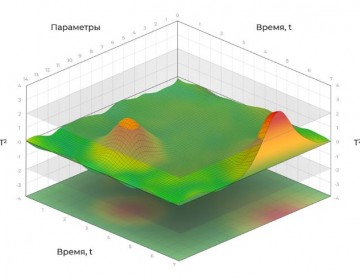

TEI calculation aims providing unique reliable and operative information on the operation efficiency of the core equipment for operational personnel and company management, in order to make decisions on performance optimization and maintenance. Continuous monitoring performance using automated systems is necessary for maintaining high efficiency of equipment. It is determined by a large volume of process parameters and specific features of the equipment producing electric power.

The creation of a TEI calculation system with deep integration into PRANA System pursues several goals and offers a range of unique possibilities to users. First of all, statistical data collected by PRANA System indicates that around 70% of all deviations detected in equipment operation are related to incorrect readings of measuring devices at generation units. This circumstance is conditioned by a range of economic, technical and structural reasons and this relation will not change considerably through modern technological development. It is this data that is used for calculation of TEI by specialists of IEDs (industrial engineering departments) at enterprises. It is easy to assume that the results of such calculations would be highly relative, and would, instead of improving production efficiency, provoke additional process and financial costs.

The new software module will perform continuous monitoring of fuel consumption to generate heat and electric power, considering the actual equipment state and tracking the trends of its change during operation. In this case, savings will be provided due to the performance of timely repair works and the equipment operation modes correction.

At present, there are several automated measuring systems on the market used for calculation of technical and economic indicators (AMS of TEI), which permit to ensure calculation of the main TEI for a power unit and СНР in general in real-time. However, compared to these, the PRANA System has considerable advantages: power unit TEI calculation is conducted in parallel with deeper analysis comprising a greater number of process parameters. This means that the System can automatically associate deviations of any indicator with a set of parameters, which served as the initial cause for the deviation.

The software system is created with the perspective of continuous improvement and life-long support conducted by the experts at the PRANA System Situational Center.

ROTEC JSC (www.zaorotec.ru) − is a company specializing in monitoring and predictive analytics of industrial equipment condition (PRANA system), design, engineering and general contractor services in the power engineering facilities and infrastructure construction, development and production of high quality honeycomb seals for the aviation industry and power engineering, highly efficient energy accumulation and storage systems based on supercapacitors, and the manufacture, modernization and maintenance of main power equipment.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices