New features of the PRANA prognostics system simplify working with big data

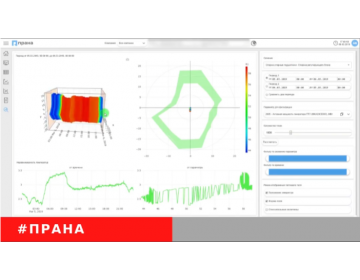

The state Register of computer programs includes the new program modules of the PRANA prognostic system. They are intended to emulate possible accidents and malfunctions, to automate technical reporting, and also to automatically update digital models after repair or service of the equipment.

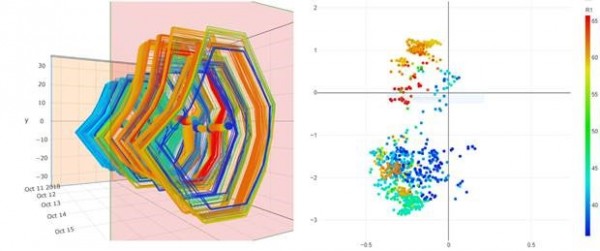

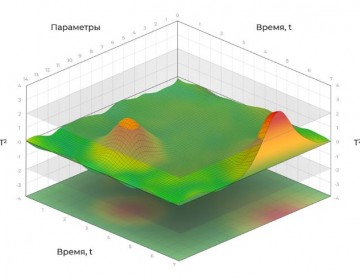

One of the new modules is designed for 3D imaging of thermal fields. With its help, the specialists of the Situation Center create visual models of temperature distribution in the equipment units. 3D imaging includes not only data about the temperature level of the sensor group, but also information about its change over time.

Fig. 1 Distribution of temperature fields for the steam turbine thrust bearing

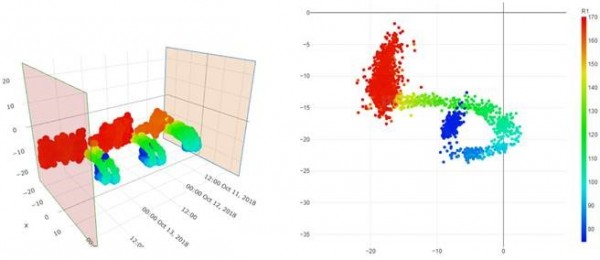

With the help of this tool, experts can analyze the condition of almost all the gas turbine units — air preparation system, air distributor, compressor stages, combustion chambers, fuel-feed system, automatic control system, and the gas turbine stages. For example, a change in the color and location of heat spots can detect an increase in pressure drops in the air filter, off-performance of the control system, pollution or damage to the compressor, uneven fuel supply and contamination of the burners in the combustion chambers, and damage to the blades of the power turbine. Moreover, 3D imaging of the thermal field is also used to analyze the state of individual units of the gas turbine that are not related to the fuel combustion cycle, for example, support bearings or generator electrical coils.

A 3D heat field map is a multipurpose diagnostic instrument that can display changes over time of any two-dimensional parameters and correlations — its visibility and ease of use greatly simplify working with big data.

Fig. 2 Distribution of temperature fields on gas turbine exhaust in different operating modes

PRANA prognostics system is an industrial IoT-solution that prevents defects and accidents in industrial equipment. The system creates a mathematical model of the unit on the basis of data on its operation in the normal state. A similar model is created and updated online – it reflects the current state of the equipment. Comparison of the two digital images facilitates determination of deviations with high accuracy. PRANA automatically identifies the top 10 causes of the deviation and calculates when they may cause a problem. The experts of the ROTEK Situational Center analyze the indications of the system and find faults in the equipment. Thus, PRANA ensures safe and efficient operation of the equipment.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices