IoT in the Russian energy industry

According to data from Rostec for 2018, 60 % of industrial enterprises in Russia are using or testing Internet of Things technologies. In the next two to three years, the IIOT market in Russia is expected to triple: from 93 billion to 270 billion rubles. The upcoming launch of the fifth generation mobile network (5G), which is best suited for big data transfer in these systems, will only strengthen this trend. This is the opinion of experts interviewed by iot.ru.

Experts:

- Armen Badalov, Vice President for Strategy, Innovation and Regional Development, Schneider Electric in Russia and the CIS

- Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC

- Gennady Nosenko, Director of IIOT Solutions at First Line Software

- Svetlana Saveliyeva, Head of the Department for Development of Industry Expertise at Softline Group of Companies

IoT is used in all segments of the electric power industry: generation, transmission and distribution, sales, and consumption. The use of the components of the Internet of Things together with other digital technologies (big data, neural networks, edge computing, and wireless networks) offers indisputable advantages such as real-time asset management, loss reduction and improved metering and distribution accuracy.

How has the Internet of Things been developing in the Russian energy sector over the past two years?

Mikhail Lifshitz: Until recently, the digitalization of generating capacities affected mainly individual power units, primarily those built under the program of power supply agreements (PSA). Automated process control systems (APCS) and monitoring technologies were introduced. The next step, now within companies, was the creation of unified systems for trading electricity. In the last year, we observe the active introduction of equipment condition prognostics systems, the leaders in this area are T Plus, Mosenergo and Tatenergo.

In the network industry sector, Rosseti is actively involved in the implementation of IoT technologies. The first digital substation in the country, Medvedevskaya, fully equipped with domestic equipment, has already been introduced in Moscow.

Svetlana Saveliyeva: In the last two years, more and more projects in the field of digitalization, energy efficiency and energy saving have been implemented in the energy sector. Large companies see digitalization as an innovative tool for managing the energy infrastructure and invest huge amounts of money in it: they introduce “digital substations”, “digital networks” and “digital twins” of power generating facilities. Among the leaders of digitalization are UES System Operator, Rosseti, FGC UES, etc.

Last year, the President of the Russian Federation instructed the government to prepare a regulatory framework that obligates to purchase Russian software and electronic components when introducing intelligent control systems for power grids. Thanks to government support for domestic manufacturers of equipment and software for the fuel and energy complex, Russian developments are becoming more widespread in the market.

Widely used are smart energy metering networks based on LPWAN technology, predictive monitoring systems for power equipment and other products from domestic vendors. It is expected that in the next 2–3 years a number of pilot projects will be launched to create the Russian “Internet of Energy” as part of the implementation of the “road map” of the “Energy” National Technology Initiative.

What are the main scenarios for using IoT in Russian energetics?

IIOT for fixed asset management

Gennady Nosenko: Sensors, controllers and RFID tags enable the transformation of companies’ infrastructure into a digital environment where each facility has “digital intelligence” and can “tell the story” of its life cycle. Companies are applying or are considering applying IIOT concepts to monitor their assets and more delicate business planning and management; they are building online diagnostic systems for predictive analysis of equipment. The leaders in the implementation of IIOT platforms are RusHydro, Rosseti, IDGC of Urals, etc.

Smart production facilities

Gennady Nosenko:Real cases of fully automated production lines based on advanced information and communication technologies that can take into account content and help personnel and equipment in solving their problems are still rare in Russia. Positive examples are the implementation of the Gazpromneft smart field in the Khanty-Mansi Autonomous Okrug where Artificial Intelligence, together with IIOT and Machine Learning, helps the staff to make decisions on the best oil recovery, field development, and improvement of recovery factor.

Predictive analytics

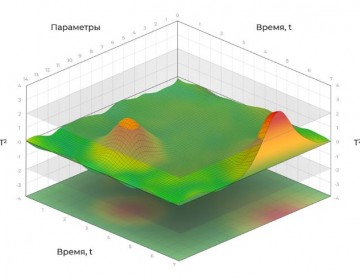

Digital twins

Gennady Nosenko: Digital twins of production facilities (or individual units) are a large and complex group of technologies based on the Internet of Things and Big Data processing solutions. Such digital models will help predict failures, reduce maintenance costs, and prevent unscheduled outages of equipment. In Russia, projects for construction of virtual prototypes of production facilities are being implemented by one of the country’s digital leaders – Rosatom. However, there are several aspects that make the creation of digital twins a very difficult task. Firstly, you need to aggregate a lot of data, therefore a highly reliable strategy for collecting and processing data is required. It should be noted that it is impossible to use raw or incomplete data, because their quality will affect the quality of the forecast.

Smart grids and digitalization of the industry

Mikhail Lifshitz: Retrofit without digitalization today is equal to technological inferiority. The most obvious window for digitalization and intellectualization of the Russian energy sector is the new PSA-2. It would be logical to start the implementation of modern intelligent systems and analytical tools with equipment that is characterized by a high cost of accident and downtime. The introduction of smart grids in the energy sector will lead to a significant reduction in technological risks, increased operational efficiency, the possibility of automatically controlling a large distributed fleet of generating equipment, and increased manageability and reduced costs of large technological complexes. Digitalization of power grids and the creation of industrial energy storage systems will increase the flexibility of the Russian power system and bring it closer to the automatic distributed dispatch.

Resource consumption monitoring

Svetlana Saveliyeva: Among the areas most ready for digitalization in the Russian energy sector, I would point out consumption monitoring and demand management, and monitoring and forecasting the condition of generating facilities and electric grids. For example, the use of a real-time monitoring and diagnostic system makes it possible to detect most of the common failures of critical and expensive equipment (gas and steam turbines, transformers, pumps, boilers and compressors). Some promising areas are: distributed electric power generation, management of the consumption profile, and identification of unauthorized connections.

Which factors influence the growth of IoT use in the Russian energy sector?

Mikhail Lifshitz: The development of distributed power generation contributes to the decentralization of the industry; the role of consumers is changing. Now, they can generate energy for themselves and sell the excess energy. The ever-growing need for a flexible and reliable power grid is driving the introduction of smart grids, which are based on IoT technology.

The large-scale use of prognostic technologies and migration to the concept of repairs “as required” with their help will make significant resources available, and will help to competently and efficiently form service budgets. Most importantly, the equipment’s reliability will become a manageable parameter.

But there are opponents to the development of IoT solutions, whom I would call “digital luddites”. These are the personnel who simply do not need transparency, while machines cannot be fooled. Fortunately, business owners and top managers have a different view of digitalization.

Armen Badalov: In its current form, the Russian energy sector is for the most part overly centralized, which makes it far from the most efficient system. Modern digital technologies and the Internet of Things, in my opinion, contribute to the improvement of the system’s efficiency at all stages – from generation to final consumption. They also facilitate better control of costs, and stimulate the development of new energy sources (renewable energy, cogeneration, transition to individual heating stations, etc.). At the same time, a positive effect can be achieved with relatively low investments.

Svetlana Saveliyeva: The implementation of IoT in the power industry is being stimulated at the federal level. In November 2017, the government made changes to the Development Strategy of the electric grid complex of the Russian Federation in terms of a gradual transition from a scheduled preventive repair system to the organization of repairs according to the actual technical condition, taking into account the consequences of failures of the basic technological equipment (risks). Such initiatives of the Ministry of Energy of Russia as the approval in Spring 2018 of the “Digital Transformation of the Electric Power Industry of Russia” program passport, as well as the development of a pilot project to develop a system for remote monitoring and diagnostics of combined cycle plants, are undoubtedly the drivers of the growth of Internet of Things usage in energetics.

The spread of IoT in Russian energetics will also be promoted by national standards in the field of “smart energy”, the Law No. 522-FZ, adopted on December 27, 2018, aimed at regulating the implementation of smart metering systems for electric energy (power), as well as a rapid reduction in the cost of sensors and cloud services.

Source: iot.ru

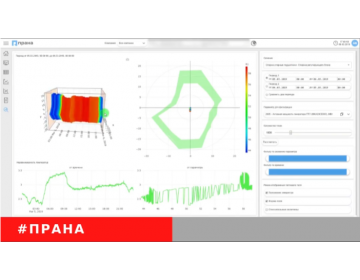

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices