Interview with Mikhail Lifshitz: Predict to Prevent

PRANA is an innovative tool that helps prevent machinery related accidents.

This new prognostic tool allows for timely response to faults and failures of various kinds of equipment thus increasing its reliability and maintainability. The tool has a rigorous scientific theoretical and practical foundation.

We asked Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC JSC, to tell us about the new opportunities offered by PRANA.

- Tell us about the background of the PRANA prognostic and remote monitoring system. Is its development caused by some kind of Zeitgeist or is it the result of scheduled works at a certain stage of the company development?

- To answer your question, I would like to tell you about the exceptional results of a routine experiment. Geneticists were to study the features of E. coli metabolism. To do this, the scientists evaluated the adaptability of different strains of the bacteria to decrease in nutrients. Imagine their surprise when one of the strains started dominating despite the extremely low amount of nutrients. Why? It’s simple. It turned out that this strain used a new and quite unexpected compound as their nourishment thanks to a random mutation. The scientists had not reduced the content of that compound in the nutrient solution, and thus the bacteria had a significant head start. And we are just like those bacteria. Being young and hungry, we didn’t mean to fight the Goliaths of the industrial market. What we wanted to do is to beat them in a game of chess.

What most OEM companies strive to do is to sell more parts and services, while we resolved to change the very logic of work with industrial equipment. OEMs had already had monitoring systems that could accumulate data for internal knowledge bases. However, such systems cannot fundamentally improve gas turbine maintenance, so we took on to create a new market of predictive analytics. And our communications with our foreign colleagues confirms that it’s us who is shaping the market.

PRANA prognostic and remote monitoring system is being developed by first-rate mathematicians and experts in the field of power equipment. Add our experience in gas turbine maintenance and steam turbine production, and — voila — you get a new product that meets the real needs of the customer. I mean, the purpose of the system is not only to detect but also to predict and localize a future failure. When you know what is going to break down and where it is going to happen, you don’t need to repair it post factum. And what is more, you know that for sure — in fact, none of PRANA diagnoses have been proved wrong yet.

- This is truly an innovation. Are there any foreign or Russian counterparts?

- Our development towards digitalization is a global trend, but we’re ahead of it in terms of our approach. IBM, SOFTWARE AG, Schneider Electric, Bosch have similar solutions, but I haven’t heard of this particular kind of prognostic tool so far. Solutions based on multilayer neural networks predict about one week ahead. Our algorithms allow for two- and even three-months-ahead predictions. Sounds pretty comforting, huh?

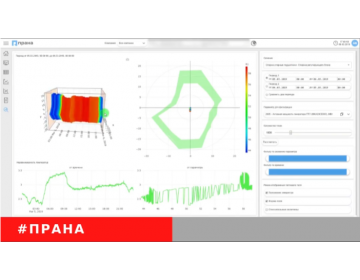

PRANA is able to predict approximately 95 per cent of various emergencies. In case of changes in readings of any of 500 gas turbine sensors, the system responds within a second, and in another 3080 seconds, it is able to identify the cause of the deviation, determine the emerging defect and its development pace, as well as to predict the time of the failure.

- What is the main purpose of the system and its functions? What is it based on?

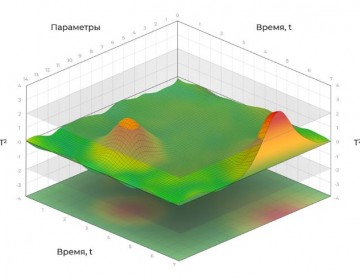

- The system is based on the theory of multidimensional faults. PRANA analyses sensor readings and builds a reference model of how a particular piece of equipment works in different modes. The system is able to adapt to a particular unit and works with all kinds of equipment from gas turbines to pumps and pumping units. Furthermore, the system accuracy improves with each hour of operation.

Naturally, the main function of the PRANA system is to predict an accident, and this already means a great deal. However, there is more to this than meets the eye. Thanks to predictability of failures, not only can the company avoid downtime and fines, but also pre-order the required spare parts — without rush and at an adequate price. You don’t have to keep a large stock anymore. Not to mention the money a company can save by monitoring the quality of works performed by its contractors and machinery operators. We all know all too well how repair budgets can escalate sometimes and how sudden and “sudden” breakdowns affect those budgets.

Such prognostic tools can improve equipment reliability multiple times even today, and in the long term, they are expected to increase business performance in general. How? The rapid development of prognostics brings us closer to predictive maintenance — the Holy Grain of health management. Having full and accurate information on reliability of each individual part of a unit, we can forget scheduled service and repair only those parts that do need repair. Need I mention how much money we can save this way?

- Has PRANA been tested in practice? Tell us about the results. Are there any prognostic data concerning accident reduction after the launch of PRANA? What are these estimates?

- As of today, PRANA has already analysed over 450 thousand hours of turbine operation. Is it a lot or a little? Judge for yourself. PRANA has already prevented one accident, or about 200 days of downtime, and has issued over 50 warnings. All of the warnings were proved to be correct, which means that it is a 100% accurate system. Well, the law of large numbers will make some adjustments to these data, but PRANA’s predicting power has been tried and verified. This means that reliability has become a manageable parameter.

Let me tell you a real life story. After decrease of the active power, one of the turbines showed increased axial vibrations in bearing No. 4. PRANA managed not only to predict when such vibration was going to rise to the level of alarm, but also helped find its cause. The problem was that increase in vibration was accompanied by temperature drops of the cooling air in the brush gear. In case of normal turbine loads, the air was heated from the rear platform of the generator where the bearing pedestal is located. In other words, the temperature drops implied cooling of the bearing assembly fixture which was not equipped with any sensors. We found out that thermal expansion of the metal in normal mode reduced the level of vibration. But after cooling, we witnessed axial play in the pedestal — an obvious design defect. Thanks to the early warning, the turbine operator had an opportunity to schedule the repair and eliminate that defect during a routine outage. The level of vibration reduced twofold and no longer increased.

- What are the prospects of the PRANA launch? Which industries can use it?

- The main advantage of the PRANA system is flexibility. Its algorithms are suitable for all kinds of equipment. We started with one of the most complex machine — a gas turbine. But we are well aware that its mathematical tools are suitable for other applications as well, such as transformers and locomotives. Predictions based on changes in the oil temperature or the current frequency — it’s all the same for PRANA. Maths capabilities are virtually unlimited in this case. The main thing is to get the data. We can always equip the machinery with new sensors as and when necessary.

As I see it, PRANA will be of most use in the spheres where equipment failure may result in loss of time, money, even deaths, that is the national infrastructure facilities — power and oil&gas industries, rail and maritime transport, aviation, as well as various lifting equipment from lifts to tower cranes and urban management systems.

- Are you planning to put PRANA to the international software market?

- We have close ties with our colleagues from South Africa, Iran, Slovenia. Naturally, the international market is ready for such technologies. But I’m also happy that Russia is bold and determined in this case. We witness interest of the Russian energy sector stakeholders, and what is more important, their readiness to the introduction of the Industrial Internet of Things. And in this context, another benefit of PRANA is that it’s not only a product of scientific progress, but also our weapon in the competition of the fundamentally new and the usual. Remember the story about E. coli?

I hope that we won’t miss these new technology opportunities. If anything, we will drive them! After all, we’ve got everything it takes.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices