Experts united in one network

Historically, writing allowed people to store knowledge. Book printing machines made this accessible, and the internet has erased the remaining boundaries. The ability to instantly share data has irreversibly changed the world.

Only the best industry experts have to fly to another city when a combined cycle gas turbine stops working at -40°C and their help is urgently needed.

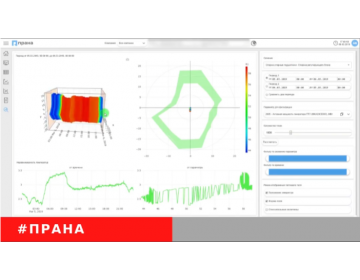

Surprisingly, there was no existing specialized system for industrial experts to work remotely and in collaboration until now. Let's be honest - using e-mail to jointly search for defects in a gas turbine is as effective as hammering a nail with foam rubber. But the situation is changing. For example, ROTEC has introduced functions for creating distributed expert communities in its PRANA prognostics system.

Preventing accidents and improving the efficiency of industrial equipment is the main purpose of the PRANA system. For five years, it was developed by a team of experienced power engineers, mathematicians, and programmers. At present, it protects 3 GW of generating equipment against accidents.

Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, notes that it was precisely the company's close cooperation with customers that made it possible to create an effective tool for solving industry-specific problems. As a result, PRANA became Russia's first industrial prognostics system and was commissioned at operating power plants. It also turned out to be one of the best in the world.

“Existing prognostics systems around the world use two techniques: statistical modeling or working with big data. We were able to combine the two approaches,” says Mikhail Lifshitz, explaining the advantage of PRANA.

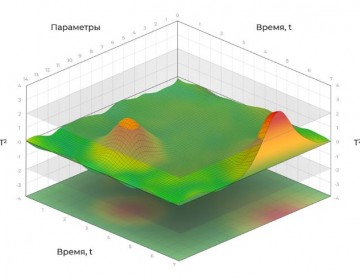

When each new piece of equipment is connected to the system, its digital image is created - a set of mathematical models describing the ideal behavior in various operating modes. Every second, the system compares the current condition of the equipment with the model condition. In case of deviations, it automatically lines up the 10 parameters that make the greatest contribution to the change in technical condition. This is where the specialists get involved, using the expert modules to develop necessary recommendations based on a huge array of previously processed data (more than one and a half million hours).

At the ROTEC situation center, experts are currently working on all nodes of equipment connected to the prognostics system. These experts include both “veterans” with dozens of years of experience, and promising young people, such as candidates of science. Eighty installations are connected to the center - gas and steam turbines, booster compressors, waste heat boilers, and generators.

Companies whose equipment is connected to the PRANA system don't just receive round-the-clock monitoring or notifications of “deviations”, but full expert support. In the course of commercial operation, more than 150 incidents have already been prevented. Moreover, while only ROTEC experts used to have access to the data, now customers are able to connect their own authorized colleagues to the system. Via secure communication channels, of course. The system has reached a fundamentally new level - for the first time in the industry, an expert center can be distributed.

“We have created a platform for organizing distributed expert teams. An experienced turbine engineer can work at one of the heat and power plants, a brilliant “vibration expert” a thousand kilometers away, and a top boilermaker at an entirely different location. Now PRANA allows us to combine the unique experience and knowledge of not just our own experts, but also the customer's best specialists. Therefore, they will be useful not only for the station where they work, but also for the entire company," emphasizes Mikhail Lifshitz.

Participants of corporate expert networks have remote access to data on the operation of machines, reports, charts and other analytics results using mobile applications, secure chat, conference calls and a thin client. The mathematical apparatus of the prognostics system undertakes all the work of analyzing the raw data, and the experts are required to make a decision and make recommendations to the station personnel. So PRANA unites experts from different cities, branches and divisions “on the job”. This kind of technology makes industrial expertise global, which opens up the possibilities for a breakthrough.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices