Downstream Digitalisation

Predictive analytics and online IIoT surveillance systems respond to modern challenges

TODAY, BIG DATA IS THE NEW OIL. NOT PROCESSING IT FULLY IS LIKE BURNING BANKNOTES TO HEAT A STOVE, AS RUSSIAN SCIENTIST DMITRY MENDELEEV APTLY REMARKED. HOWEVER, IT IS WORTH NOTING THAT RUSSIAN INDUSTRY IS IN GOOD SHAPE REGARDING IMPLEMENTATION OF IIOT SOLUTIONS WITHIN THE CRITICAL INFRASTRUCTURE SECTORS

American management consulting company McKinsey included Russia in the top 5 most digitally developed countries. The report shows that from 2011 to 2015, the volume of digital economy in the country increased by 59 % (8.5 times faster than in any other sector). In 2025, its share of GDP could potentially triple and hit 10 trillion rubles.

ROTEC – a Russian energy turbine maintenance company – has built up the largest information database on rotary generators in the country. In 2011, they began developing systems that would allow them to use this information to its full potential. Four years later, Russian R&D developers launched the PRANA hardwaresoftware package, the first of its kind, commercially available, IIoT solution independent of OEM that monitors and predicts the condition of energy systems, 2 – 3 months before a possible incident may occur. The company claims that the name PRANA was formed by combining syllables of two Russian words for "PRedictive ANAlytics". This facility is much like a high-tech oil refinery, processing tremendous amounts of big data to make high-precision predictions about the behaviour of various types of industrial equipment, constructing a digital infrastructure that integrates all the systems of the enterprise and monitors technical and technological relationships.

The PRANA facility is much like a high-tech oil refinery, processing tremendous amounts of big data to make high-precision predictions about the behaviour of various types of industrial equipment

"Any complex machine, be it a turbine or energy converter, will break down occasionally. And the control panel reacts only after something has malfunctioned. What do we do? We go out and look for the signals long before the breakdown occurs or when it is "set to happen", and we warn the experts about it. In reality, the depth of our prognosis is approximately 3 months for power generating facilities". - Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC JSC

The PRANA ecosystem allows us to combine various types and models of industrial equipment within a single expert environment.

Since 2015, this facility has been operating on a 24/7 basis and allows us to prevent unforeseen malfunctions and breakdowns of industrial equipment, making the entire production chain transparent, and thus predictable and highly effective. After 5 years of the PRANA facility being in operation, the Russian energy industry has made remarkable progress. Having started with one thermal power plant in Perm, by 2020, ROTEC has digitised and secured 22 electrical power units under the protection system in 9 regions across Russia and Kazakhstan with total capacity of 3.5 GW. Experts have highlighted that PRANA has now virtually become the industry standard for power generating companies, and insurance companies provide more favorable conditions to those whose equipment is under the control of the System. These power engineering benchmarks seemed appropriate in other enterprises that included crucially important infrastructure, mainly in the oil and gas sector. Back in 2019, the System found its way into the equipment of Gazpromneft's oil production facility. Gazpromneft-Vostok LLC and ROTEC JSC implemented a project to digitise the oil production companies' equipment at the Shinginsk field. The PRANA prognostics system was connected to four 6-megawatt gas-turbine units (GTU-6PM) manufactured by UEC-GT-R&D Saturn, three booster compression units of type TAKAT 77.3-23M3 MCC1 manufactured by Kazankompressormash JSC, and two compressor units of type JGF/4 manufactured by ARIEL, USA. Generally speaking, as of today, the PRANA package is integrated into equipment with a total value of 5 billion USD.

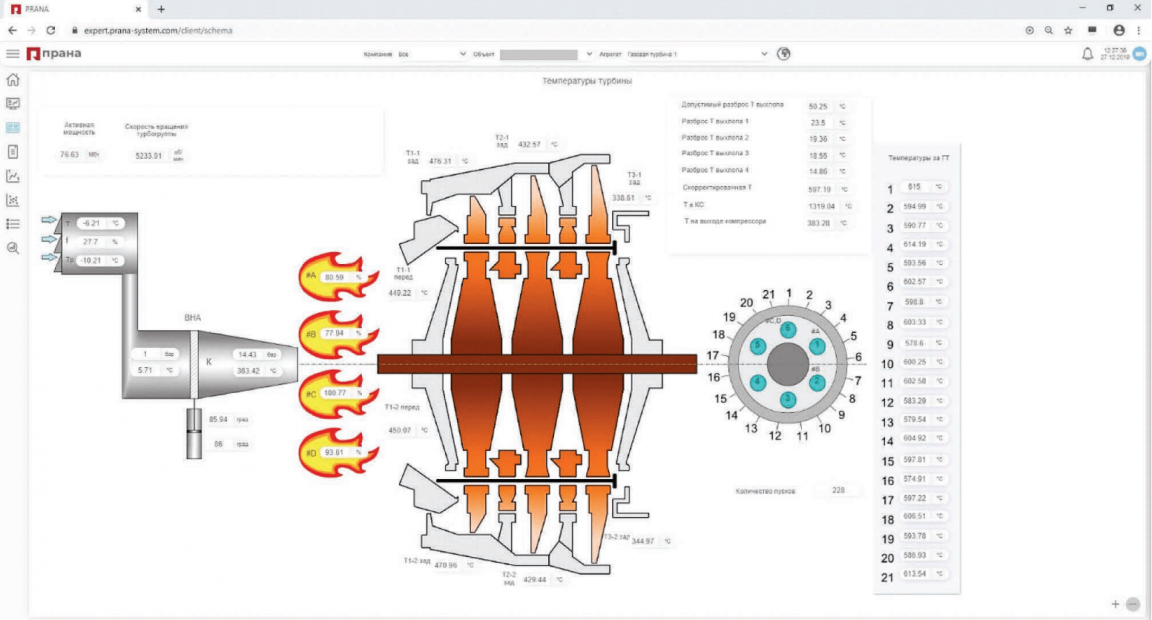

Mnemonic diagram of a gas turbine in the interface of the PRANA hardware-software package

Hardware-software packages can be briefly described as follows. Based on the analysis of historical data, a mathematical model of the equipment’s operating condition is created. When operating in realtime, the package continuously monitors the status of the connected equipment and informs the operating personnel about detected trends in developing emergency modes with recommendations for the maintenance of normal operations. Mathematical models, machine learning and artificial intelligence determine the interdependence of operational parameters that cannot be determined by existing local control systems. The PRANA package reveals long-term changes in the technical conditions of the equipment and provides additional time to locate and liquidate a problem at an early stage, whilst the local APCS (automated process control system) protects the equipment from fast-developing dysfunctions. PRANA has already been integrated into practically every APCS on the market: I&C Tekon, I&C ALSPA ControGaz, I&C KVINT 7, I&C KRUG, I&C Mark VIe, I&C PCS7, I&C OC6000e, I&C Ovation, I&C SPPA-T3000.

Various monitoring systems, predominantly operated by equipment manufacturers, have extensive industrial applications. However, it is necessary to highlight two important aspects. Firstly, every manufacturer uses their own personal solutions and interface for their equipment. This means that control over the parameter settings will have to be monitored intermittently on various devices. Whereas PRANA combines all the indicators within one ecosystem. Secondly, it might be somewhat difficult to be objective when speaking of a control system provided by the manufacturer interested in the supply of spare parts and providing maintenance services... just as difficult as it would be having to rely on a fox for the security of a chicken coop.

PRANA package mobile version on an iPad

The economic impact from applying this hardware-software package consists primarily of improving equipment reliability and accident prevention. With the electrical sector, the cost of every unforeseen breakdown results in millions of roubles lost. ROTEC provides examples of the economic benefits deriving from the implementation of the package at one of the largest generating enterprises in Russia: over several years, it has reduced losses by over 5 times and reduced the number of incidents by almost 3 times.

This spring is proving an uneasy time for the entire world, yet industrial digitalisation has taken on new colours, giving enterprises the opportunity to respond to the costs of self-isolation in a timely manner without compromising business processes. In late March 2020, PRANA unveiled yet another frontier that enables users to remotely access all data and expert environments within the package in a matter of hours. The introduction of remote operation mode has become a massive stress test for the entire hardware-software package, bringing together over 140 professionals, energy and oil professionals from eight regions across Russia and Kazakhstan in one digital office.

"The solution that we conceived as a means of improving economic efficiency for customers (with the possibility of connecting their own professionals) proved to be one of the most effective ways of operating the technical division of the company in an emergency situation. Cloud technology solutions do not compromise employee productivity and help maintain employee health". - Maxim Lipatov, Technical Director for PRANA Hardware-Software Development

Back in 2019, the PRANA hardware-software package introduced features that enabled the establishment of a dispersed expert community. Bringing together experts to repair and operate various equipment such as gas and steam turbines, genepackage, boilers, converters and so on in one place is extremely costly, both in terms of resources and time. Therefore, an appropriate solution was developed that allows experts (through secure communication channels between the Situation Centre of the PRANA facility and linked sites) to have complete remote access to the results of analytical data processing, forecasts and tools to work with the operational parameters of equipment. In case the need arises, switching to distributed work has been made possible without reducing efficiency.

If previously only ROTEC experts had access to data, now clients were able to connect their authorised colleagues to the package as well (via secure communication channels). Members of corporate expert networks gain remote access to machine data, reports, charts and other analytical results through mobile applications, secure chats, conference calls and thin-client. The mathematical unit of the prognostics system takes over all the work on raw data analysis, while experts are required to take decisions and provide the station personnel with recommendations. Thus, the PRANA facility brings together experts from different cities, branches and departments without interrupting production. The package has reached a fundamentally new level – for the first time in the industry, an expert centre can be dispersed.

Challenges to modern civilisation, which has no boundaries, are diverse and abundant. Yet today, we already possess digital solutions capable of not only building production processes more responsibly, but also making once large and sluggish industrial systems more flexible, rapidly adapting to economic demands, as well as to emergencies that no one is immune to.

Source: 100th issue of Neftegaz.RU

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices