AlfaStrakhovanie and ROTEC begin cooperation in the field of technological risk forecasting

AlfaStrakhovanie and ROTEC have signed an agreement on cooperation in the field of technological risk forecasting and insurance. The companies have agreed on the possibility of using the PRANA industrial equipment condition prognostics system for retrospective analysis of incidents which have led to the occurrence of insured events. Implementation of the system will speed up the payment of insurance claims. The partners also plan to explore the possibility of developing experimental scoring models for assessing risks associated with the operation of industrial equipment and its insurance cost.

“Profound data analysis makes it possible to identify the true causes of accidents, which may include both constructional defects of equipment and improper use by employees. In the future, companies using prognostic analysis systems will be able to benefit from additional special terms of insurance for their production capabilities by reducing the potential for accidents and increasing transparency of operation and technical condition,” Egor Trishkin, lead key account manager of AlfaStrakhovanie PLC, explains.

“Use of predictive analytics systems is capable of changing the existing practice of technological risk insurance. Prognostics is not just an effective way of preventing failures, but an objective criterion for investigating accidents which have already occurred. We expect that our cooperation will bring insurance of industrial risks to a new technological level,” Marianna Svetlosanova, Marketing and Business Development Director of ROTEC JSC’s PRANA project, commented.

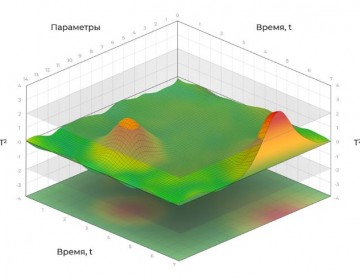

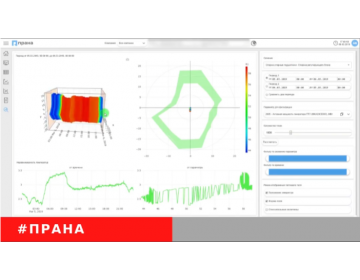

As it analyses archive data on the operation of each specific unit, the PRANA System constructs adaptive mathematical models, with which it compares equipment operation parameters in online mode and constructs technical status change trends. It allows defects to be detected at a very early stage in their development, two or three months before they show themselves, i.e. lead to an accident. Implementation of the PRANA System at industrial facilities can improve equipment reliability, reduce unscheduled downtime and, above all, avoid accidents. The same method is used for retrospective analysis of incidents, with the PRANA System becoming an objective tool for identifying the causes of accidents.

AlfaStrakhovanie Group includes AlfaStrakhovanie PLC, AlfaStrakhovanie-Life LLC, AlfaStrakhovanie-OMS LLC and Medicine AlfaStrakhovanie LLC. The Group’s own capital is RUB 14.3 bln. AlfaStrakhovanie Group is part of the financial and industrial Alfa-Group Consortium (Alfa-Bank, Alfa Capital, А1, Rosvodokanal, X5 Retail Group N.V.). Under its license, the Group offers more than 100 insurance services, including life and accident insurance products. AlfaStrakhovanie Group’s regional network includes more than 270 regional departments all over Russia. More than 24.8 mln customers use the Group’s services all over Russia. AlfaStrakhovanie Group has also been rated by Fitch as BB according to the international scale, and received the ruAA+ highest reliability rating from the Russian rating agency Expert RA.

ROTEC JSC: The industrial holding which is engaged in the PRANA industrial equipment status prognostics system, design, engineering and general contracting in the construction of power engineering facilities and infrastructure. The company also develops and manufactures highly efficient systems of energy storage and accumulation based on supercapacitors. The PRANA System is an objective digital tool for detecting the causes of accidents at industrial facilities.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices