60-MW Turbine Unit

One of important objectives of the technical modernization at the Arkhangelsk PPM is the renewal of the turbine room in the first thermal power plant. Currently, the mill is preparing to replace turbine unit No. 7. Manufacture of its new version is approaching completion; in October, delivery of the equipment to the mill will begin.

Replacement of “Number Seven”;

TPP-1 is the energy heart of the mill. It is closely linked with every production unit of the mill. Everything is important here, however, turbine units along with boilers and coupling transformers are the main type of equipment at the power plant.The turbine unit consists of two basic elements: a steam turbine and a turbine-type generator driven by it. It is designed to convert the kinetic energy from steam into electrical energy. Thanks to the operation of turbine units, the required amount of electricity is generated for the production units of the mill and the residential sector of Novodvinsk. Replacing the old turbine unit, which has exhausted its service life, is an important step in the process of updating the power generating capacity of the APPM.

The new version of “Number Seven” includes a PT-608.9/1.9 digitalized steam turbine manufactured by the Ural Turbine Works (a company of ROTEC holding), and a TF-60N-2UZ turbine-type generator manufactured by NPO Elsib PJSC (in Novosibirsk).

– “The old Number Seven” used hydrogen cooling of the generator,” Igor Bulygin, Director of TPP-1, comments,

– “The new unit will be air-cooled, which is more fireproof.”.

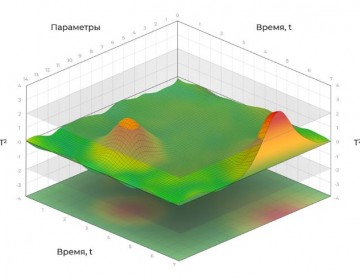

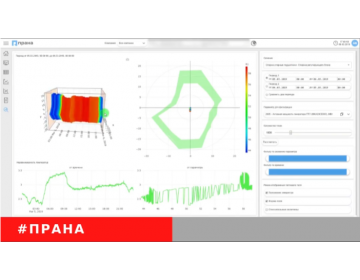

Despite the fact that the future turbine unit No. 7 has the same capacity as the previous one (60 MW), it belongs to the new generation of technology. In particular, the turbine will be equipped with an electronic and hydraulic automatic control system (like in turbine No. 5 installed in 2013). The use of the modern PRANA diagnostic system developed by ROTEC JSC will facilitate monitoring of the technical condition of the steam turbine during operation.

The PRANA system is responsible for the effective monitoring of the technical condition of equipment and its parameters (such as, vibration condition), and early detection of defects, thereby preventing emergency situations. PRANA will increase the level of operation reliability of the power generating facility.

The total cost of the construction project of turbine unit No. 7, taking into account all the work, is estimated at more than 2 billion rubles.

A contract for the future

– “Arkhangelsk PPM JSC has signed a contract with ROTEC for the supply of a new steam turbine on October 11, 2018,” Pavel Smirnov, the Production Development Director of the mill, says, “This supplier has been selected due to their extensive experience in the production and maintenance of power generating equipment, and completion of high-tech projects in the energy sector.”

The key points were the high level of competencies of the holding in the field of power generating equipment and the conformity of its products to the best world standards. The quality of domestic-made turbines is no lower than that of their imported counterparts.

As Ivan Panasyuk, General Director of ROTEC JSC, emphasized on the day of signing the contract, the Ural Turbine Works, where a new turbine for TPP-1 is being manufactured, has 80 years of experience.

During this time, more than 900 steam turbines have been created for clients not only in the post-Soviet space, but also around the world.

The manufacturer of the turbine-type generator for turbine unit No. 7 – Elsib machine-building enterprise (Novosibirsk Turbogenerator Works) – is also one of the best-known manufacturers of turbine equipment in the country. During the course of its existence, the company has manufactured 800 turbine-type generators with a total capacity of 66 million kW. Of these, 580 turbine-type generators are installed at 181 power plants in Russia.

The beginning of the project was preceded by a thorough review and approval of the technical documentation. In December 2018, the acceptance test of the turbine-type generator was held at the stand of the manufacturer, NPO Elsib, which was attended by the working group of the Arkhangelsk Pulp and Paper Mill, headed by Andrey Chikshov, Chief Engineer of TPP-1.

The steam turbine manufacturing process is currently being completed. In October 2019, the turbine is expected to arrive at the mill. After that, the previous turbine unit No. 7 will be stopped and its dismantling will begin. Then, construction and installation works, installation of equipment of the new “Number Seven” and its commissioning will take place. An important task for manufacturers and contractors will be the connection of the new turbine unit to the existing utilities of thermal power plant No. 1.

TPP-1 is developing

The turbine equipment of TPP-1 will continue its development. As soon as the commissioning of the seventh turbine unit is completed, the Arkhangelsk PPM will be able to replace other units of turbine equipment.

There are further plans to install a new turbine unit No. 6 with a capacity of 30 MW, then turbine unit No. 8 with a capacity of 60 MW. Each of these is in operation today, and is regularly subjected to industrial safety examinations, however, they are already close the limit of their service life because of their technical condition. The experience gained while working on the “Number Seven” will help in the implementation of these capital-intensive projects.

The power generating facilities of the mill are expected to change in the future, including changes related to the transition to environmentally friendly fuel, i.e. natural gas. Four boilers operating at TPP-1 will be converted to gas fuel, and three new gas boilers will be built. This will involve putting the entire chain of equipment related to solid fuel out of service. Replacing the turbine units of the first thermal power plant of the APPM is a significant event in the renewal of power generating facilities of the mill.

The employees of the first thermal power plant are also involved in technical modernization projects implemented at other production facilities of the mill. At the same time, they are solving current problems associated with keeping the equipment of TPP-1 in good working order.

In fact, the first thermal power plant of the mill, after its commissioning in 1940, went through three stages of capacity expansion. Each of these stages was associated with an increase in the technological capacities of the Arkhangelsk PPM. Today we are witnessing a new period in the development of the power generating facilities of our company.

Reference information

The last work on the installation of a new turbine unit at TPP-1 of Arkhangelsk PPM was completed in 2013. At that time the fifth turbine unit, which had expired its service life, was replaced. The previous version of this machine had been operating since 1960.

The new turbine unit No. 5 has a capacity of 30 MW. It is mounted in the location of the former “Number Five”. The steam turbine was manufactured by Kaluga Turbine Works, the turbine-type generator was manufactured in the city of Lysva, Perm Region.

Author: Pavel FASONOV

Source: bumazhnik.ru

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices