UTW digitalised steam turbine to ensure efficient and smooth waste processing

Ural Turbine Works (ROTEC Holding) has developed Russia’s first turbine for waste incineration plants — Kp-77-6,8. This makes it possible to abandon the use of expensive equipment from foreign producers in favour of domestic technologies. Furthermore, due to the use of ROTEC Holding’s prognostic technologies, the new turbine now has the highest level of reliability.

Unlike convenient power plants, the performance of waste incineration plants is measured not only in Watts of electric power, but also in tonnes of waste processed. In case of failure of the generation equipment, consumers can get their power from other generation facilities; however, lack of waste processing capacities cannot be compensated for in the same way.

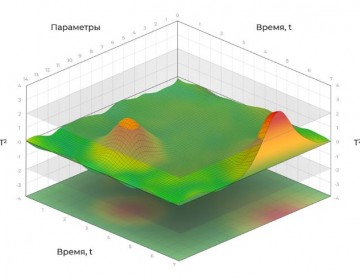

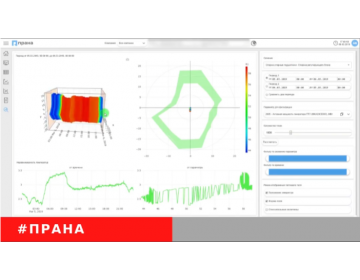

That is why the new machine from UTW uses the PRANA Prognostics and Remote Monitoring System developed by ROTEC Holding. PRANA identifies deviations in the operation of equipment 2-3 months before they cause a failure. The use of predictive analytical technologies not only prevents potential accidents, but also enhances transparency, reliability and efficiency of operation.

“Over several years, we have been developing a line-up of turbines and technical solutions for a power island of waste disposal facilities using either direct incineration or pyrolysis. I am confident that the Ural turbines will promote the development of this type of generation and thus will contribute to an improvement in the environmental situation in Russia,” Mikhail Lifshits, Chairman of the Board of Directors of Ural Turbine Works, stressed.

The new UTW machine has been designed in a one-cylinder version and has a capacity of 75 MW, which is enough to supply 80,000 apartments with power. It is based on operationally proven design solutions and state-of-the-art patented technologies.

Kp-77 has been developed on the basis of technical specifications provided by the project customer AGK-1 and the project engineer HITACHI Zosen Inova AG, who are implementing a project to construct municipal solid waste treatment plants in the Moscow Region and the Republic of Tatarstan. It is expected that they will help to reduce the level of waste burial from 95% to 40% in the Moscow Region by 2023, while the Republic of Tatarstan will reach a target of zero burial by that time. Ural Turbine Works has successfully passed a production and engineering capacity audit conducted by HITACHI Zosen Inova AG.

Ural Turbine Works JSC (www.utz.ru) is one of Russia’s leading machine-building enterprises in the area of design and production of power equipment. Founded in 1938, the enterprise currently specialises in producing steam turbines, servicing and modernising steam and gas turbines. It is part of ROTEC Holding.

ROTEC JSC (www.zaorotec.com) is an industrial holding. The areas of company activity involve the PRANA system for predicting industrial equipment status; design, engineering and general contracting services associated with construction of power and infrastructure facilities; development and production of highly efficient systems for energy storage and accumulation using supercondensers; and manufacturing, modernising and maintenance of primary and auxiliary power equipment.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices