Gas turbines of the three major manufacturers have been connected to the PRANA prognostics system

ROTEC specialists successfully connected two Alstom GT13E2 gas turbines operated at Novogorkovskaya CHPP of PJSC T Plus to the PRANA prognostics system. The total capacity of the equipment is 360 MW. The PRANA mathematical model monitors and every second updates 344 operating parameters of the connected Alstom turbines.

Thus, today the PRANA system supports the equipment of all three major gas turbine manufacturers - General Electric, Siemens and Alstom. All the main equipment of power generating units, including steam turbines of UTW, GE and Siemens, generators manufactured by ABB, General Electric, Electrosila and Alstom, heat recovery steam generators (Taganrog Boiler-making Works Krasny Kotelshchik, ZiO-Podolsk, Belenergomash-BZEM LLC, Istroenergo Group, BBS, EMAlliance and HRSG), as well as the booster compressor stations BORSIG, Howden and GEA Grasso GmbH, is connected to the system. PRANA operates with all automated process control systems common in Russian power generation - GE, Siemens, Alstom, Tekon and Kvint.

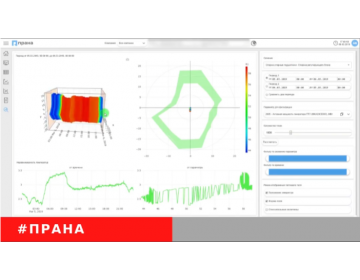

Today PRANA ensures safe and reliable operation of more than 80 power generating equipment units. Its overall capacity exceeds 3.2 GW and the cost is 3 billion US dollars. In 2018 the project team introduced a number of new functions into the system - technologies for creating distributed expert teams, mobile applications for remote access of experts, plant personnel and power generating company management, neural networks for defect localization, modules for vibration diagnostics and automated calculation of plant components residual life.

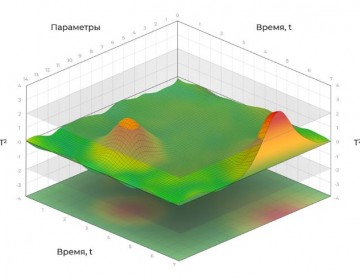

The PRANA prognostics system detects defects in equipment operation 2-3 months before they can lead to an accident. It automatically creates an operating equipment reference model, with which it subsequently compares the equipment's sensor readings. PRANA finds the differences between the digital image and the actual state of the installation, and also determines the reasons that have led to them. This method facilitates the detection of defects in advance, and the objective assessment, and thus monitoring, of the equipment's technical condition.

ROTEC JSC (www.zaorotec.com). Company business areas: the PRANA system for forecasting the state of industrial equipment; designing, engineering and general contracting for the construction of energy and infrastructure facilities; development and production of highly efficient energy accumulation and storage systems based on supercapacitors; manufacturing, modernization and maintenance of basic power equipment.

The PRANA Predictive Analytics and Remote Monitoring System has received another update of the operating system.

The industrial holding ROTEC JSC and Group-IB, one of the leading developers of solutions for detecting and preventing cyberattacks have entered into a cooperation agreement to ensure technological and cybersecurity of critical infrastructure facilities. The agreement was signed at the International Industrial Trade Fair Innoprom 2021 and will allow ACS and IS specialists of enterprises to observe and take proactive measures to prevent incidents caused both by service wear of equipment and as a result of cyberattacks.

The industrial Internet begins with the introduction of systems based on mutual penetration of information technologies and automation devices of manufacturing equipment, such as the systems of remote monitoring and diagnostics. One of the inspection methods of the equipment’s condition is its continuous monitoring, which is a necessary condition for the transition to a service system on the operating condition

According to Mikhail Lifshitz, Chairman of the Board of Directors of ROTEC, Russian power engineering company, the venture capital market in its present state is currently raising people whose aim is not to create a winning product, but just to raise funds. With regard to his business, Mr. Lifshitz abandoned the speculative component and headed for the long-term integration of ideas into production.

Despite the hazy weather and pouring rain, the yachtsmen were in a terrific mood! Three crews of racing yachts in Olympic Class SB20, mainly represented by employees of ROTEC, PRANA and TEEMP, took the whole winners podium in the amateur competition. For most of the participants, it was their first-ever experience of this kind – and they claimed victory straight away!

The trend towards digitalization and flourishing of the service economy have led to the emergence of a new model – Maintenance-as-a-Service. Let’s explore how it’s organized and the benefits that it offers to business.

The Internet of Things (IoT) integrates devices into a computer network and allows them to collect, analyze, process and transmit data to other facilities via software, applications or technical devices