A gas turbine outage is a major and by no means straightforward event. Plant personnel are to strictly adhere to the established procedure, and monitor numerous parameters. No wonder that slight performance deviations can be missed.

The System That Never Sleeps

A gas turbine outage is a major and by no means straightforward event. Plant personnel are to strictly adhere to the established procedure, and monitor numerous parameters. No wonder that slight performance deviations can be missed.

Today, the PRANA Prognostics System ensures reliable operation of over 80 generator units, including 6 GTE-160 gas turbines. When one of the units was taken out of service, the system identified a jacking oil system malfunction and prevented an unscheduled outage.

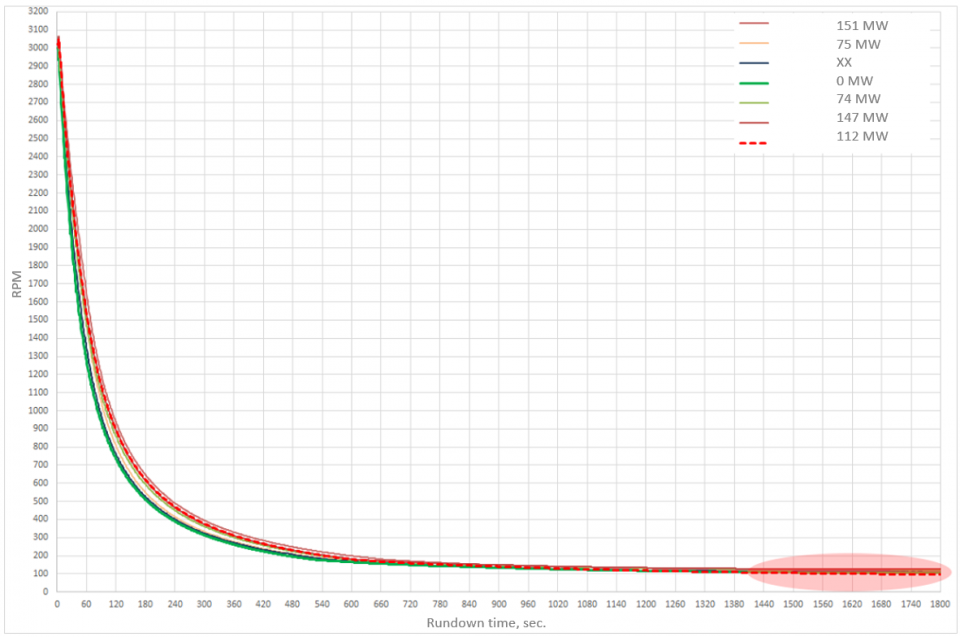

The GTE-160 gas turbine was stopped for external reasons: the gas pressure upstream of the emergency stop valve had dropped. The turbine rundown within the specified period was typical for this kind of unit, so the standard monitoring system did not identify any issues.

GTE-160 gas turbine rundown diagram for various initial active power values

As specified in the operating procedure, after the turbine is stopped, the barring gear keeps rotor moving for another 24 h. During this time the rotor cools down gradually, while its rotation prevents non-uniform cooling and rotor bowing.

When running at high rpms, an oil wedge is naturally formed between the journal bearing and the rotor. At low rpms, the oil jacking system operates: a pump delivers oil to the bearing at over 130 kg/cm2 and literally “jacks” the rotor with an oil film.

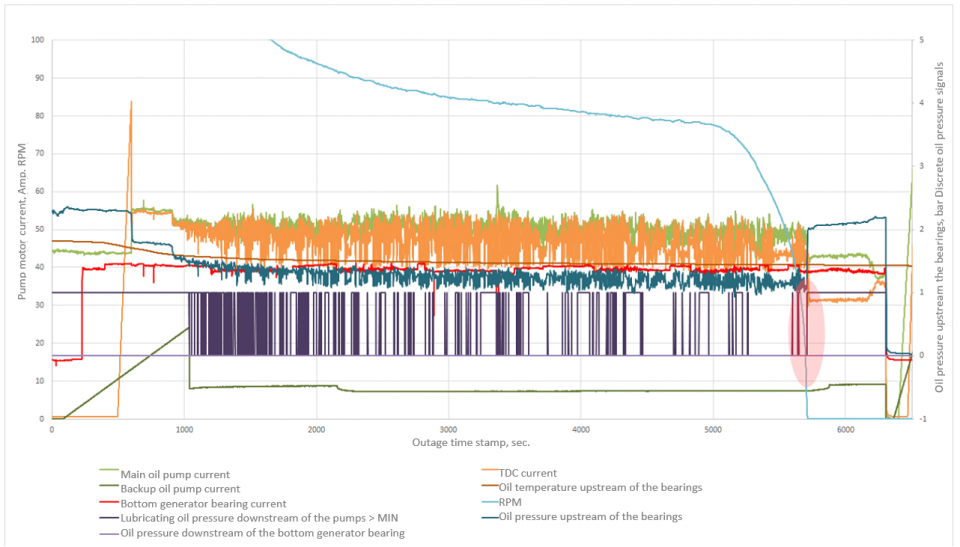

In the case under consideration, the jacking oil system activated as the rpm dropped to 200. While operating online, PRANA identified an abrupt degradation: the oil pressure had dropped below the threshold, and the jacking pump motor current had reduced from the rated 63 to 40 Amps.

Under the criteria of the standard control system, this was not an emergency: the oil jacking was working, albeit with some deviations. However, we promptly notified the plant about the possibility of spontaneous halting of the rotor. Further, we recommended an inspection of the jacking oil pump and its safety valve, and checking the oil distribution between the rotor journal bearings.

The rotor continued to spin for another hour, and then stopped as the rpm reduced to 77, since the jacking pressure was insufficient to keep it in motion:

Turbine outage schedule

With the early warning, the plant personnel avoided non-uniform rotor cooling by barring it manually till the jacking oil supply was restored. Manual rotor barring is an operation listed in the manual. Without the barring, it would have been impossible to start the turbine for at least three days.

Since PRANA analyzes the equipment operation in every condition (including after being stopped), the turbine outage period did not increase because of the jacking oil system malfunction. As the gas supply was resumed, the turbine continued its operation. Our customer avoided losses and fines for power delivery interruption.

A gas turbine outage is a major and by no means straightforward event. Plant personnel are to strictly adhere to the established procedure, and monitor numerous parameters. No wonder that slight performance deviations can be missed.

The human mind is unable to track the correlations between hundreds of diverse values. Instead, it can develop a prognostic system to help. Learn how PRANA finds concealed relations and reveals equipment defects.

A cogeneration plant equipped with the PRANA prognostics system re-launched a BORSIG T-Jet 70-4 booster compressor after repairs. After the compressor had been started, a PRANA Situational Center operator noticed low primary gas pressure at the seals of compressor stages 1-4.