A cogeneration plant equipped with the PRANA prognostics system re-launched a BORSIG T-Jet 70-4 booster compressor after repairs. After the compressor had been started, a PRANA Situational Center operator noticed low primary gas pressure at the seals of compressor stages 1-4.

The Story of a Booster Compressor

A cogeneration plant equipped with the PRANA prognostics system re-launched a BORSIG T-Jet 70-4 booster compressor after repairs. After the compressor had been started, a PRANA Situational Center operator noticed low primary gas pressure at the seals of compressor stages 1-4.

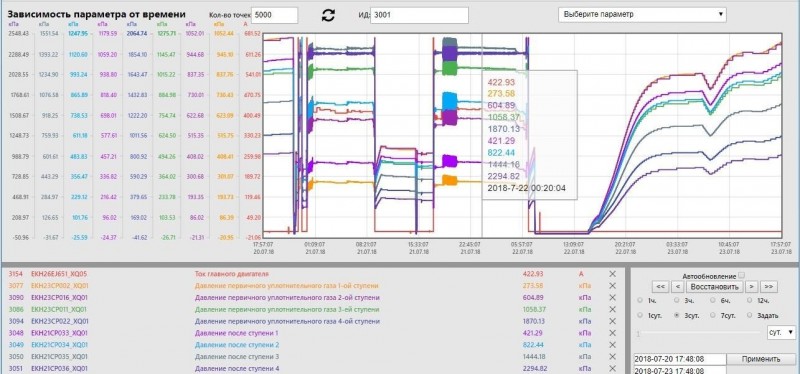

Seal gas pressure variation

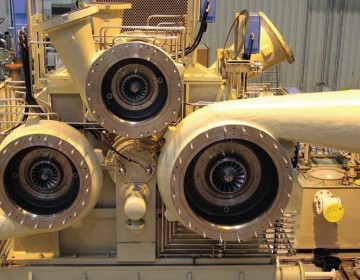

The T-Jet 70-4 compressors operate at high shaft and impeller rpms. Each stage has a dry seal on the shaft between the impeller and the gear box, which prevents process gas leaks.

The seal system delivers seal gas: purified primary (process) gas and secondary (nitrogen) gas, and compressed air.

The compressor gas seals are at the high-pressure impeller side. Lower primary seal gas pressure reduces the internal labyrinth flow, which ensures ingress of no fluid/particles into the seal cavity, and prevents unpurified process gas ingress into the seals. Subsequently, that leads to unpredictable seal ring degradation.

One of the possible reasons for reduced primary seal gas pressure is the closing of the gas supply valve on the booster compressor pressure to the seals line, or incorrect adjustments of the differential valves delivering the primary seal gas to the compressor stage seals.

For this reason, we recommended: first, check if the seal gas valve prom the delivery line was opened. If it was opened, adjust the primary seal air pressure drop individually for each stage.

So, PRANA has prevented a booster compressor outage that would have resulted in losses and fines for the generating company due to prolonged inoperability of the combined-cycle gas turbine unit. On the average, PRANA monitors 50 to 100 variables for each booster compressor in real time. Among them are the compressor oil inlet pressure, seal differential pressure, gas leakage pressure for each stage, auxiliary oil cooler pressure, stage inlet temperature, bearing temperature, main motor winding temperature, compressor outlet temperature upstream and downstream of the gas cooler, compressor inlet gas temperature, oil temperature downstream of the oil cooler, casing temperature, main motor amperage, compressor inlet gas flow, IGV inlet gas flow, bearing vibration, main motor vibration, impeller rpm, impeller axial shift, nitrogen receiver pressure, nitrogen quality, among many others.

A gas turbine outage is a major and by no means straightforward event. Plant personnel are to strictly adhere to the established procedure, and monitor numerous parameters. No wonder that slight performance deviations can be missed.

The human mind is unable to track the correlations between hundreds of diverse values. Instead, it can develop a prognostic system to help. Learn how PRANA finds concealed relations and reveals equipment defects.

A cogeneration plant equipped with the PRANA prognostics system re-launched a BORSIG T-Jet 70-4 booster compressor after repairs. After the compressor had been started, a PRANA Situational Center operator noticed low primary gas pressure at the seals of compressor stages 1-4.